Interview with CEO Edie Dillman for ‘What We Love: New Mexico’

We’re honored to share a recent interview with our CEO and co founder, Edie Dillman, featured by What We Love: New Mexico. Their work centers people, place, and care, telling stories about what it truly means to love where you live and to take responsibility for its future.

We’re honored to share a recent interview with our CEO and co founder, Edie Dillman, featured by What We Love: New Mexico. Their work centers people, place, and care, telling stories about what it truly means to love where you live and to take responsibility for its future.

In the interview, Edie reflects on building homes in New Mexico that prioritize comfort, affordability, and long term resilience, while supporting local jobs and honoring regional building traditions. It’s a thoughtful conversation about housing, community, and why the places we build in and for really matter.

Watch the full feature here →

January Newsletter by B.PUBLIC Prefab - Looking Ahead

In Looking Ahead, we share updates on the Fort Collins Design for 2030 pilot, a cliffside Co.LAB project in Nova Scotia, national event appearances, and recent recognition of our Director of Practice. A snapshot of the partnerships and progress shaping the year ahead.

January’s Newsletter, Looking Ahead, sets the tone for how we are approaching 2026: with active partnerships, built momentum, and a clear focus on making high-performance construction easier to deliver. From being named a partner in the City of Fort Collins’ Design for 2030 pilot, to advancing Co.LAB collaborations and celebrating design leadership within our team, this edition reflects the ecosystem approach that defines B.PUBLIC. If you missed it, you can read the full newsletter archive here.

Press Release: B.PUBLIC Prefab Named Partner in Fort Collins ‘Designed to 2030’ Pilot Program

The City of Fort Collins has selected a team led by Building Wellness, with B.PUBLIC Prefab, Steven Winter Associates, Inc., and HereAbout Homes as project partners, to develop pre-approved, high-performance home plans through the Designed to 2030 Pilot Program. Read the full Press Release here.

The City of Fort Collins has selected an interdisciplinary team led by Building Wellness, with B.PUBLIC Prefab, Steven Winter Associates, Inc., and HereAbout Homes named as project partners, to develop a new set of pre-approved, high-performance home plans as part of the Designed to 2030 Pilot Program. The initiative is focused on simplifying the path to above-code, all-electric residential construction while supporting the City’s long-term climate and housing goals.

Below is the full press release announcing the program, the project partners involved, and the vision for how these plans will support builders, homeowners, and Fort Collins’ long-term climate and housing priorities.

Building Wellness Selected by City of Fort Collins to Lead ‘Designed to 2030’ Pre-Approved High-Performance Home Plans Pilot Program

Fort Collins, CO - [Jan 27, 2026] - Building Wellness is pleased to announce that we have been selected by the City of Fort Collins to serve as the Project Lead for the Designed to 2030 - Pre-Approved High-Performance Home Plans Pilot Program, an initiative focused on making it easier and more cost-effective to build all-electric, high-performance homes in Fort Collins. Together, these efforts support a broader vision within the Fort Collins “Our Climate Future” policy and a community desire that everyone lives and works in healthy, energy- and water-efficient buildings that are designed to transition toward zero emissions over time.

Fort Collins joins thousands of cities that offer “stock” plans to help builders and homeowners save thousands of dollars in design fees, reduce permitting timelines, and offer plans designed for ease of construction with prefab options that can cut 3-6 months from construction timelines. The city is investing in stock designs specific to meet city energy codes and housing demands. Plans will be complete construction plan sets and pre-evaluated through energy modeling, high-efficiency mechanical system design, and advanced building science creating additional savings that can directly support housing attainability for local builders and homeowners.

The pilot program will create a portfolio of available residential pre-approved plans that will include multiple high-performance home designs, at least one of which will be ADU-compliant, intended to reduce upfront design costs, shorten permitting timelines, and remove common barriers builders face when pursuing above-code performance. The team selected will work closely with the city and community outreach programs to create a selection of homes that suit the ambitious energy goals, Fort Collins’ unique housing styles, climate appropriate systems, and a size mix to serve occupant demands for the area.

“Buildings play a critical role in our climate future,” said Brad Smith, Building Energy Code Project Manager for the City of Fort Collins. “The Designed to 2030 Pilot Program helps ensure that new projects in Fort Collins are designed with long-term performance, resilience, and community benefit in mind while strengthening partnerships across the building industry.”

“We’ve heard consistently from designers and builders that the path to high-performance housing can feel complex and expensive,” said Karen Ramsey, Founder of Building Wellness and Fort Collins resident. “This program is an opportunity to lower that barrier. I see it as a meaningful opportunity to help translate the City’s climate goals into design solutions that are practical, affordable, and grounded in the realities of how homes are built in our community.”

Building Wellness will lead an interdisciplinary team that brings together technical, architectural, and construction expertise, including Steven Winter Associates, Inc., B.PUBLIC Prefab, and HereAbout Homes.

Steven Winter Associates, Inc. brings more than five decades of experience in energy efficiency and high-performance building consulting, supporting residential projects across North America in meeting ambitious performance targets.

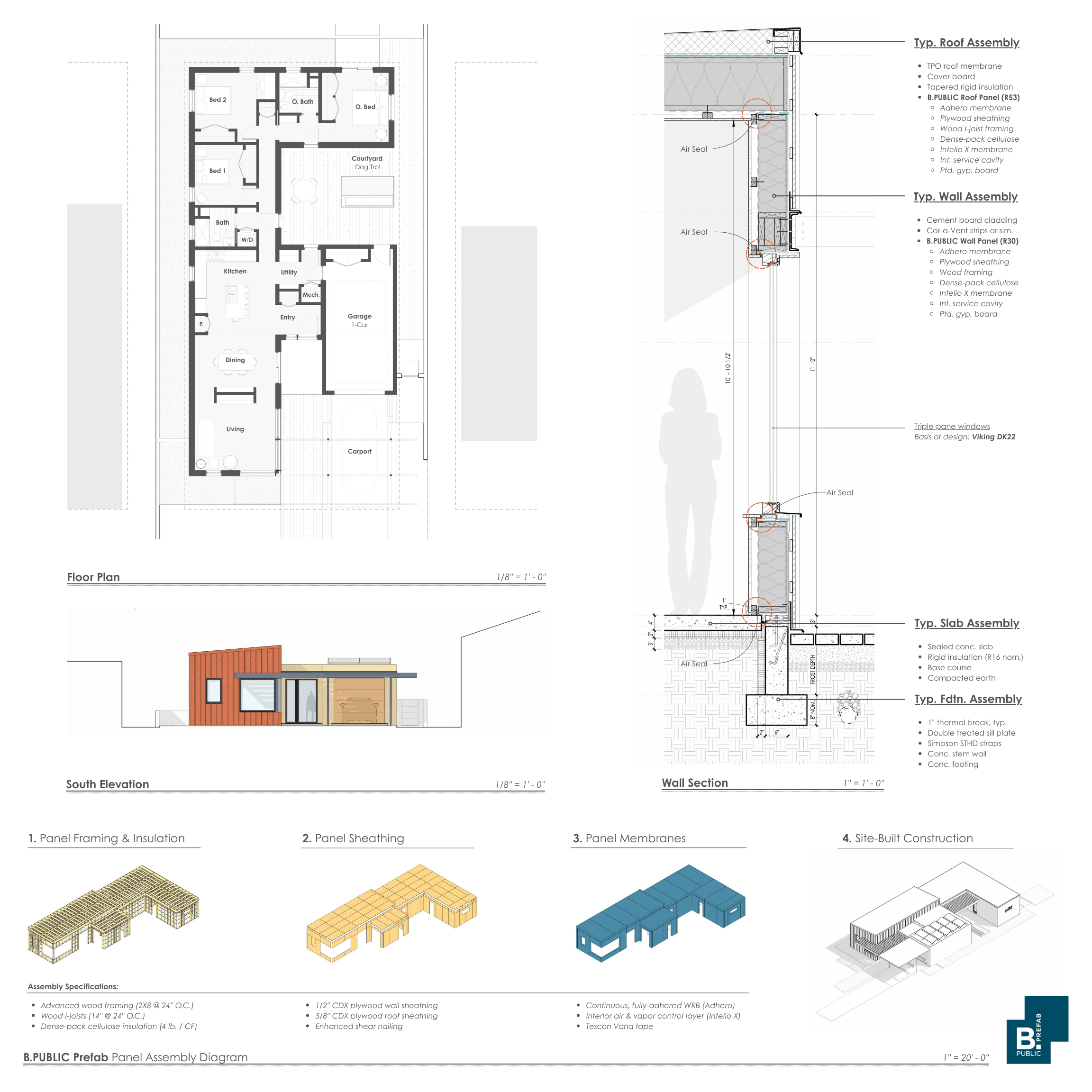

B.PUBLIC Prefab contributes expertise in panelized building envelopes that prioritize airtightness, durability, and constructability to reach optimal energy and comfort performance, helping reduce both construction waste and long-term energy demand. They have developed a catalog of standard home plans that align with the goals of the Pilot to support rapid adoption of best practices.

HereAbout Homes is a firm specializing in predesigned architectural residential designs with projects across the US and Canada. They will provide expertise in design excellence with goals focused on livability, aesthetics, and broad market use.

“Fort Collins is leading the way with a path to Net Zero for all new home construction in the US and we believe that this program and the portfolio of high-performance home plans that it will create will be a pilot for Colorado and the US,” said Edie Dillman, B.PUBLIC Prefab.

Together, the team will deliver a set of pre-approved home plans designed to support builders, thrill homeowners, and align residential construction with Fort Collins’ long-term climate and housing priorities.

About the Designed to 2030 Program

The City of Fort Collins Designed to 2030 - Pre-Approved High-Performance Home Plans Pilot Program is intended to simplify the delivery of above-code residential buildings by providing pre-approved designs and associated engineering support. The program advances local climate and housing goals by creating more efficient permitting pathways for high-performance, all-electric homes.

About Building Wellness

Building Wellness is a Colorado-based sustainability strategy and high-performance building consulting firm. The firm specializes in Passive House methodologies, energy modeling, embodied carbon analysis, and wellness-centered design, supporting communities and project teams in delivering durable, healthy, and climate-aligned buildings.

For more information about the Designed to 2030 Pilot Program, please contact:

Karen Ramsey

Founder, Building Wellness LLC

karen@buildingwellnessllc.com

Interview with Co.LAB Partner Holly Mumford of Hereabout Designs.

Co.LAB partner Holly Mumford of Hereabout Designs shares insights from a recent B.PUBLIC Prefab project in Nova Scotia, reflecting on collaboration, early design decisions, and how a simple, repeatable plan can adapt beautifully to different landscapes through high-performance prefab construction.

Our Co.LAB program is built around collaboration, shared learning, and the belief that great design and high-performance prefab are strongest when architects are brought into the process early. Through Co.LAB, we partner with designers to adapt and evolve repeatable plans using B.PUBLIC Prefab panel systems, balancing architectural intent with constructability, energy performance, and place-based design.

In this interview, we sat down with Co.LAB partner Holly Mumford of Hereabout Designs to talk about our recent project in Nova Scotia, Canada. Starting from Hereabout’s pre-designed plan The Hangout, Holly worked closely with our team and her clients to customize the home for its coastal setting while learning the nuances of panelized, high-performance construction. The conversation offers a candid look at collaboration, early decision-making, and what it means to design repeatable homes that still feel deeply rooted in place.

1. Let’s start with the story behind our recent Co.LAB project in Canada. What drew you to this site and these clients, and how did the location in Nova Scotia influence your design approach?

HM: I was brought into the project through our collaboration with B.PUBLIC, which was very exciting. Jennifer & David fell in love with “The Hangout” design, while bringing a few of their ideas and customization requests to the table. It was easy to appreciate the site - it’s incredibly beautiful. I love the traditional vernacular of Prince Edward Island and knew The Hangout would be a nice contemporary shift for the area.

2. Hereabout has such a distinctive design voice - rooted in place, yet quietly modern. How did those values show up in this home’s layout, materials, and connection to the landscape? How do you then connect that to a repeatable plan?

HM: Thank you! The Hangout was intentionally designed to be a simple, gable home on the exterior. I actually designed it during covid with the idea for it to be a place of gathering for family and friends. The house is designed on an axis - one axis cuts down the entry and one down the ridgeline & hall. This axis starts to define the public spaces from the private spaces - a necessary element for folks to share spaces (living/kitchen/dining) and also have spaces to retreat to. Since The Hangout is part of our pre-designed plan collection, it’s always exciting to see the design placed on different landscapes. I think what is successful in the design is that the shape and scale is very minimal and grounded, so it can morph into different landscapes nicely.

3. What was that experience like from a designer’s perspective working with B.PUBLIC panels and our team... both the opportunities and the learning moments that come with working in a new prefab system?

HM: I learned so much working with B.PUBLIC’s team and truly think of them as an asset to creating a successful build project. While the house is seemingly simple there are a few technical areas that we needed to flush out together. This was really insightful to learning about the efficiencies and construction of panelization. It’s fun to be able to understand the system and how a design can be achieved with prefab.

4. The Co.LAB partnership is about experimentation and shared learning. How did collaboration with the B.PUBLIC team shape your process, and what insights would you share with other architects considering high-performance prefab?

HM: I think the biggest learning curve for me was in terms of decision making and understanding that some decisions needed to be made earlier than I’m used to in a traditional project. I only see this as a positive - being ahead of the game on decision-making in a project only makes it more successful. For example, fine-tuning window sizing and fixing those sizes forced me, as a designer, to have a deadline and dive deeper into design with the clients earlier. It was excellent.

5. Designing for comfort, resilience, and energy performance often requires tradeoffs. What were some of the biggest design decisions or details that made this project stand out to you?

HM: We were faced with a few potential “trade-offs” but as a team (design, prefab, and structural) we were able to get creative and solve them without having any impact on the design or spaces. It was helpful to be able to have options with the B.PUBLIC team on how to approach certain areas of the design.

6. Is there anything else you’d like to share about this project or your experience as a Co.LAB partner... lessons learned, surprises along the way, or what you’re excited to explore next with B.PUBLIC?

HM: I’m truly excited to see this project come to life! It’s been such a positive experience working as a Co.LAB partner. Every project has lessons and surprises - but we were successful in this project by working as a team throughout the process. I’m excited to explore some new designs specific for prefab - more to come! :)

Offsite Builder: “Hire for Attitude, Train for Skill”

B.PUBLIC Prefab was recently featured in Offsite Builder for its people-first approach to workforce development. By hiring for attitude and pairing curiosity and commitment with hands-on training, B.PUBLIC is helping builders gain the skills and confidence needed to deliver high-performance prefab projects.

Recently featured in Offsite Builder, B.PUBLIC Prefab’s hands-on installer training demonstrates how investing in people accelerates both company growth and broader industry adoption of high-performance prefabrication. The two-day program, hosted at the Las Vegas, NM factory, immerses participants in Passive House principles, practical sealing and rigging techniques, and coordinated panel installation — equipping even experienced builders with the mindset and skills needed for offsite construction.

Beyond technical instruction, the training embodies a core belief that attitude matters most: B.PUBLIC Prefab prioritizes individuals who are curious, adaptable, and eager to learn, reflecting the idea that companies should hire for attitude and train for skill (a philosophy underscored in the article). The result is not just workforce development for B.PUBLIC but a strengthening of the broader prefab community, inspiring builders and designers to rethink traditional construction approaches.

JD Scott’s ‘Greta House’ Awarded for Leadership in Sustainable Practice by AIA Santa Fe

JD Scott, Director of Practice and Lead Architect at B.PUBLIC Prefab, was honored by the AIA Santa Fe chapter with the Leadership in Sustainable Practice Award for Greta House, a high-performance Passive House project advancing affordable, resilient design.

Congratulations, JD Scott 🎉

AIA Santa Fe Honors Leadership in Sustainable Practice

We are proud to celebrate JD Scott, Principal Architect and Director of Practice here at B.PUBLIC Prefab, for receiving the Leadership in Sustainable Practice Award from the AIA Santa Fe.

This award recognizes Greta House, a project that exemplifies environmental responsibility, innovation in sustainable design, and long-term stewardship of natural resources. Designed by JD, Greta House is a compact, high-performance home that brings together Mid-Century Modern ideals with Passive House-level performance. At just 1,300 square feet, the project prioritizes affordability and replicability through prefabricated assemblies, durable materials, and efficient systems.

Named in honor of architect Greta Grossman, the home reimagines the resilient 21st-century tract house. Shaded courtyards, a solar-powered carport, and a strong connection to outdoor living extend the footprint, while fire-resistant detailing and drought-tolerant landscaping address the realities of a changing climate, particularly in the American West.

JD’s work on Greta House reflects what we value most at B.PUBLIC Prefab: thoughtful design that makes high-performance, low-carbon housing more accessible. We are grateful to work alongside a leader whose practice proves that sustainability and beauty can go hand in hand, and whose vision continues to push the field forward.

Congratulations, JD. This recognition is well deserved.

See his boards here:

New America: “Completing the Housing Innovation Loop: From Policy to Product Entrepreneurs”

B.PUBLIC is featured in New America’s The Rooftop as an example of a housing product entrepreneur using panelized building systems to help translate housing innovation and policy ambition into homes that actually get built.

We are pleased to be featured in New America’s The Rooftop, a platform that spotlights practical, systems-level solutions to the housing crisis. In the article, B.PUBLIC is recognized as a housing product entrepreneur developing scalable, panelized building systems that bridge the gap between housing policy goals and real-world delivery. The feature situates our work alongside innovators focused on repeatable, adaptable construction methods that can help unlock more attainable, high-performance housing across diverse regions and regulatory environments.

Prefab & High-Performance Housing Workshop – Milwaukee

We led a day-long workshop in partnership with the City of Milwaukee’s ECO and Moxie Development Collaborative, sharing building science insights and showcasing a full-scale prefab mockup. That mockup now resides at the University of Wisconsin–Milwaukee’s architecture department, where it will continue to inspire the next generation of designers and builders.

Last week we joined the City of Milwaukee’s Environmental Collaboration Office (ECO) to host a full day of free, in-person workshops focused on prefab construction, building science, and modern housing solutions. The sessions brought together builders, architects, developers, policymakers, and community members for an engaging look at how off-site construction methods can help Milwaukee reach its housing and climate goals. Attendees explored real-world applications through classroom learning and a hands-on mockup built for the event.

Thank you to the City of Milwaukee’s Environmental Collaboration Office (ECO) for inviting us to be part of their vision for a more sustainable, high-performance future for housing. Their leadership in convening this event demonstrates a deep commitment to resilient, climate-ready communities.

We’re also grateful to our sponsors — Moxie Development Collective and the Custom Residential Architects Network of AIA Wisconsin — for helping make this day of free educational programming possible.

The Housing Workshop brought together builders, architects, policymakers, and residents for a hands-on exploration of prefabrication and building science. Our classroom sessions and full-scale mockup helped participants see how thoughtful design and modern manufacturing can work together to deliver durable, efficient, and beautiful buildings — faster and with greater quality control.

Prefabrication isn’t just an innovative way to build; it’s a scalable path toward high-performance housing. By bringing precision and repeatability to the construction process, prefab methods make it easier for cities like Milwaukee to meet ambitious carbon and resiliency goals while expanding access to better homes for everyone.

As our CEO shared after the event, “You probably got more building science than you expected, but you really got a crash course on the power in your hands to build a resilient city.” That same full-scale mockup now lives on at the University of Wisconsin–Milwaukee School of Architecture and Urban Planning, where it will continue to educate future architects and builders.

Milwaukee is leading the way in green construction and housing innovation — and we’re proud to stand alongside this community in the good work ahead.

Santa Fe New Mexican: “Playing it cool: Northern New Mexico IceBox Challenge measures future of homebuilding”

Article in Santa Fe New Mexican: Playing it cool: Northern New Mexico IceBox Challenge measures future of homebuilding, posted August 8, 2025, by Cormac Dodd

B.PUBLIC Prefab proudly supported the Northern New Mexico Ice Box Challenge by donating our high-performance panels to a Passive House–designed tiny home built by local youth. This demonstration highlighted the impact of energy-efficient construction on sustainability and workforce development.

B.PUBLIC Prefab is honored to have contributed high-performance design and materials to one of the three tiny homes showcased in the Northern New Mexico Ice Box Challenge, as reported by the Santa Fe New Mexican. This innovative public demonstration, held near the New Mexico State Capitol, featured homes built to varying energy efficiency standards: Passive House, 2021 New Mexico Residential Code, and 1950s-era construction. Each home was filled with approximately one ton of ice to test how well different building methods retain thermal energy.

Our Passive House–designed home, constructed by participants in the YouthWorks program and Santa Fe Habitat for Humanity, exemplifies how integrating best practices in energy efficiency can serve as both a teaching tool for future tradespeople and a model for sustainable housing solutions. Following the event, the homes will be delivered to the Esperanza Shelter, providing safe emergency housing for families in need.

Read the full article here:

Playing it cool: Northern New Mexico IceBox Challenge measures future of homebuilding

Posted Aug 8, 2025, by Cormac Dodd

KRQE News: “At-Risk Youth Get Involved in Construction, Filling Gap Left by Retirees”

Article in KRQE News: At-risk youth getting involved in construction, filling gap left by retirees, posted August 8, 2025, by Natasha Lynn

B.PUBLIC Prefab is excited to contribute high-performance panels to one of the three new tiny homes built by local youth near our HQ in Santa Fe, New Mexico. This Passive House home, along with a tiny home built to 1950 standards and one built to the 2021 IECC building code, will be tested in the Ice Box Challenge, showcasing how applying best practices in energy efficiency can help train the next generation of tradespeople.

B.PUBLIC Prefab is proud to support a local youth construction project in Santa Fe, New Mexico, by donating our high-performance prefab panels to one of three new tiny homes. Built by students from ECO High School and the Youthworks program, this home is being constructed to Passive House standards, alongside homes built to 1950 standards and the 2021 IECC building code. The homes will be tested in the Ice Box Challenge, demonstrating the impact of applying best practices in energy efficiency to both training the next generation of tradespeople and building better, more sustainable structures.

This tiny home, which will be delivered to the Esperanza shelter, offers a place of refuge while showcasing how high-performance building practices can make a real difference. We’re excited to see these young builders gain hands-on experience with cutting-edge construction techniques, helping them prepare for careers in the trades while contributing to the community in a meaningful way.

Read the full article here:

At-risk youth getting involved in construction, filling gap left by retirees

posted Aug 8, 2025, by Natasha Lynn

B.Public Prefab and Passive House BB Announce Collaboration to Deliver Pre-Designed Passive House Plans for LA Fire Rebuild Effort and Beyond

Los Angeles, CA — B.PUBLIC Prefab is proud to announce a groundbreaking collaboration with Bronwyn Barry of Passive House BB to offer pre-designed Passive House-standard home plans tailored for families rebuilding after the devastating Los Angeles wildfires—and for climate-conscious homeowners everywhere. This innovative partnership launches with the debut of SustAIN HAUS, a new high-performance home honoring architectural master Gregory Ain and the iconic Case Study homes lost to the fires.

Los Angeles, CA — B.PUBLIC Prefab is proud to announce a groundbreaking collaboration with Bronwyn Barry of Passive House BB to offer pre-designed Passive House-standard home plans tailored for families rebuilding after the devastating Los Angeles wildfires—and for climate-conscious homeowners everywhere. This innovative partnership launches with the debut of SustAIN HAUS, a new high-performance home honoring architectural master Gregory Ain and the iconic Case Study homes lost to the fires.

Combining Passive House BB’s leadership in ultra-low energy design with BPublic Prefab’s streamlined prefab delivery system, this initiative addresses urgent housing needs while setting a new standard for sustainable, resilient architecture in fire-prone regions.

“Our COLLAB with Bronwyn Barry brings together decades of innovation in performance architecture and prefabrication,” said Edie Dillman, founder of B.PUBLIC Prefab. “SustAIN HAUS is not just a house—it’s a model for flexible resilience, beauty, and climate leadership.”

“Passive House BB [phBB] is delighted to launch our Collab with long-time friends and fellow Passivhaus pioneers, B.PUBLIC Prefab. We’re super excited to finally leverage the speed and scalability of prefabrication to expand our delivery of moderately priced Passive House homes. Keep an eye out for our upcoming designs. We’ll be highlighting California’s rich architectural vernacular while baking in all the quality detailing and performance requirements to easily make them all certified Passive House.”

These pre-designed plans are available now for families rebuilding after fire loss, as well as for municipalities, developers, and individual homeowners seeking to reduce their carbon footprint without compromising on design integrity or comfort. A full portfolio of homes will be released this spring including KraftHAUS (a classic California bungalow) and KraftHAUS Modern.

SUCCESS Magazine: Preservation and Profit: 4 Companies That Use Sustainable Business Practices to Help Protect the Earth

The building blocks to found panelized building system company B.PUBLIC Prefab fell into place during a conversation cofounders Jonah Stanford and Edie Dillman had with their eldest daughter. She wanted to know what their generation was doing to fight climate change. The question resonated.

Excerpt - Full Article

BY Ashley M. Biggers, Kristen Tribe, Em Cassel and Tess Lopez

Just last fall, I’d packed a small pink duffel bag with enough clothes to sneak away for a couple of days to a place that had long been teetering near the top of my bucket list: New River Gorge National Park in West Virginia. Something about the way the park’s iconic bridge stretched across such a cavernous drop in the landscape—a feat accomplished by humans, no less—made me ache to see it in person.

Standing near the bridge was every bit as wonderful as I had hoped for—better, even. But what I didn’t expect to steal my breath away was the view from the rear of the Canyon Rim Visitor Center: an unimpeded panorama of the park’s namesake whitewater river powerfully cutting through the canyon. It was a gray, cloudy day that cast the river in a minty-blue hue and lent a vibrancy to the orange and yellow trees surrounding it.

Tears welled up in my eyes. I was in awe. That such surreal beauty could be so easily accessible felt like a privilege nearly too heavy to bear. And yet it is accessible to us, along with dozens of other national and state parks that are safeguarded for the sole purpose of preserving the land so generation after generation can experience wonder and appreciation for the world we live in.

And thank goodness for that, because our continually developing world comes at a price. Our conveniences are exchanged for air pollution; our aesthetic for deforestation. Wildlife are losing their homes to make way for subdivisions, and the power that makes all of this happen has recently driven the effects of climate change to worrying new heights.

We can’t stop progress, but individuals and corporations alike can mitigate its downfalls through sustainability. Small changes to our habits—conserving water and energy, recycling, reducing food waste—can minimize the impact on our natural world.

Several companies have taken up the mantle in this regard, implementing sustainable practices in their business models or producing Earth-friendly products. Here are four that are showcasing what it means to value preservation alongside profit.

—Tess Lopez

B.PUBLIC Prefab

The building blocks to found panelized building system company B.PUBLIC Prefab fell into place during a conversation cofounders Jonah Stanford and Edie Dillman had with their eldest daughter. She wanted to know what their generation was doing to fight climate change. The question resonated.

Stanford, AIA and now B.PUBLIC Prefab’s chief technical officer, had been working in sustainable building and felt he was pressing the boundaries of the eco-friendly measures he could accomplish with traditional building. Dillman, now CEO, was working to fill education and skills gaps and was confronting labor shortages in, among others, the building industry. Founded as a public benefit corporation in 2019, B.PUBLIC Prefab seemed a natural evolution. Along with cofounder Charlotte Lagarde, the company has taken a radical approach to construction and has affected the sustainability, affordability and accessibility of homes.

Reflecting on her conversation with her teenagers, Dillman says, “Our kids [are] pushing us toward this stuff…. That hesitation that we’ve developed experience of—Well, it’s not how it’s been done, or is it really worth it?—their generation is already there…. If there’s a better way… of course you do that. They’re just already so far advanced in their thinking and sustainability that they do have reason to be frustrated with our generation.”

Based in northern New Mexico, the company manufactures prefabricated pieces that can be quickly assembled like Lego blocks to form the shell of a house. Building the panels in climate-controlled factories achieves 95% less waste; gone are the dumpsters full of construction waste. The airtight finished product is also incredibly energy efficient; they take 80% less energy to heat than homes built to standard requirements. Dillman compares B.PUBLIC Prefab homes to insulated thermoses: whatever goes in stays hot or cold, without additional effort to keep it that way. “If we build houses that way, they’re nearly net zero before we’ve even begun,” she says.

Educating builders and homeowners has been a hurdle—though both groups of stakeholders have adopted the product in New Mexico, Colorado, California and other locations. “I don’t think [people] are empowered to understand how much they can affect the long-term health [of a building]. There’s a lot of building to science to relay, and it takes time,” Dillman says.

Amid housing shortages and sky-high home prices, B.PUBLIC Prefab is also helping build faster and more affordably. Builders can frame, insulate and seal a house in a matter of days, rather than weeks or months. Faster building times also mean lower costs because builders can reduce the carrying costs they have to manage and which they pass on to consumers via home prices.

Following the lead her children’s generation is setting, Dillman believes sustainability should be integrated into every company—and not as an afterthought. “I don’t think we can be in business and not be working on climate and climate change. Everyone is affected by it,” she says. “And really, if we’re not doing something good, [you have to figure out how to] change your practices or assess, really, is that business necessary at this moment?”

—Ashley M. Biggers

Mariana Pickering Joins B.PUBLIC Prefab as Chief Brand Officer and Community Director

B.PUBLIC Prefab Welcomes Mariana Pickering as Chief Brand Officer and Community Director

B.PUBLIC Prefab has named Mariana Pickering—internationally recognized leader in Passive House education and high-performance construction—as its new Chief Brand Officer and Community Director. With more than 15 years of experience bridging advanced building science and practical application, Pickering joins B.PUBLIC to help accelerate the adoption of climate-conscious prefab solutions across North America. Her leadership marks a pivotal step in the company’s mission to reshape the future of energy-efficient building through collaboration, education, and innovation.

B.PUBLIC is thrilled to welcome Mariana Pickering as its new Chief Brand Officer and Community Director, beginning in June 2025. A recognized leader in Passive House education and community engagement, Pickering brings an extensive network of high-performance builders, architects, and industry professionals to her new role.

With a mission to revolutionize energy-efficient construction, B.PUBLIC Prefab delivers panelized building systems designed to meet and exceed Passive House standards — offering unparalleled comfort, durability, and carbon-conscious design. As the company continues to grow, Pickering’s expertise in Passive House market development, brand strategy, and community engagement will play a pivotal role in accelerating adoption.

“I’ve spent my career working to bridge the gap between research and real-world construction,” said Pickering. “B.PUBLIC Prefab represents the future of high-performance building—efficient, healthy, and scalable solutions for a changing world. I’m excited to help amplify this mission and build a movement around better buildings.”

B.PUBLIC Prefab was founded on a shared belief that homebuilding in the U.S. needed a better path forward—one that addressed energy efficiency, labor shortages, and the climate crisis simultaneously. The company’s roots trace back to co-founder Architect Jonah Stanford, who pioneered Passive House design in America and worked tirelessly to simplify the approach for practical application. His vision for a panelized, off-site system took shape in 2019 when the first B.PUBLIC Prefab home was installed in just two weeks at 10,000 feet elevation in New Mexico. Partnering with Edie Dillman and Charlotte Lagarde, who brought their expertise in education, workforce development, and environmental advocacy, the trio founded a woman-led Public Benefit Corporation to address both the climate crisis and housing shortage.

Prior to joining B.PUBLIC Prefab, Pickering co-founded and led Emu Passive, an internationally recognized leader in Passive House training and construction standardization. Over the past 15 years, she helped professionals across North America and Australia implement Passive House strategies, strengthening the global network of builders and consultants dedicated to high-performance construction.

As B.PUBLIC Prefab enters its next phase of growth, Pickering’s contribution to the leadership team will strengthen the company’s deep ties to the Passive House community and expand its impact across North America. As the company’s only West Coast-based team member, she’ll be supporting national impact while anchoring outreach in the Pacific Northwest.

“Mariana’s joy and passion for building science and her dedication to construction and architectural professionals makes her a powerful addition to our leadership team. We have had the pleasure to have her as a colleague for many years and and now we are thrilled to have her boundless energy and expertise at B.PUBLIC Prefab,” announces Edie Dillman, CEO.

Join us for a virtual happy hour to meet Mariana Pickering, our new Chief Brand Officer and Community Director - Tuesday, June 17th, at 4pm Mountain Time (3pm PT / 6pm ET).

The event is open to familiar faces and new friends, alike. Anyone interested in how to join the B.PUBLIC builder community is encouraged to attend with questions. CEO, Edie Dillman, will be on hand to help answer and welcome you.

Ice Box Challenge Comes to New Mexico

The Northern New Mexico Ice Box Challenge, set to take place in Summer 2025, is a building science demonstration project to highlight energy-efficient building practices, open pathways to trades-careers for local youth, and offer one solution for urgent housing needs. As part of a global initiative, Santa Fe will join a list of cities worldwide that have hosted this innovative event.

Groundbreaking Project Aims to Showcase Energy-Efficient Building Science, Open Trades Pathways for Local Youth, and Offer a Housing Solution for Northern New Mexicans in Need

by Santa Fe Area Home Builders Association

Santa Fe, NM — A coalition of housing, educational, and community care organizations, including Santa Fe Area Home Builders Association, Santa Fe Habitat for Humanity, Esperanza Shelter, Santa Fe Community College, Youth Works, Early College Opportunities, B. Public Prefab, and National Association of Home Builders, announce the Northern New Mexico Ice Box Challenge for 2025.

The Northern New Mexico Ice Box Challenge, set to take place in Summer 2025, is a building science demonstration project to highlight energy-efficient building practices, open pathways to trades-careers for local youth, and offer one solution for urgent housing needs. As part of a global initiative, Santa Fe will join a list of cities worldwide that have hosted this innovative event.

The IceBox Challenge will feature three tiny homes constructed and exhibited by youth with coaching by local trade professionals. Each tiny home will be constructed to different building efficiency standards - from ultra-efficient passive house standards, to a 2021 modern code, and a 1950's era construction standard.

All three tiny homes will be displayed near the NM State Capital building and loaded with approximately one ton of ice for the demonstration. Exposed to the summer sun, the amount of ice left in each house after the exhibition will demonstrate how different construction methods drastically impact energy consumption and how changes to building codes contribute to climate solutions.

Empowering the Next Generation

For the first time in IceBox Challenge history, high school-aged youth will participate in the construction work, gaining hands-on experience in cutting-edge energy-efficient construction techniques. The challenge not only educates but also opens up pathways toward careers in construction, design, and skilled trades.

Community Impact

Post-challenge, the tiny homes will serve as safe emergency housing for the Esperanza Shelter, reinforcing the project’s commitment to social impact and community well-being.

A Collaborative Effort - The IceBox Challenge unites a diverse team of contributors:

ECO High School: Constructing a tiny home that meets New Mexico Residential Building Codes (2021).

Santa Fe Community College: Building and then Retrofitting (after the exhibition) a lower-performing 1950s-era home with energy-saving upgrades.

YouthWorks and Habitat for Humanity: Building tiny homes to the Passive House standards using advanced construction and insulation techniques.

This hands-on public event invites the community to witness the power of energy-efficient design, helps open pathways into the trades for young people, and assists with emergency housing for a local women's shelter. Sponsorship opportunities are available to support youth involvement and sustainable housing initiatives.

Focused on the Future in New Mexico

New Mexico’s growing popularity presents an opportunity to develop innovative affordable housing models for its expanding population. Fortunately, one woman-owned, public-benefit corporation has stepped up to the challenge. B.PUBLIC Prefab launched in 2019 to make climate-friendly homes more accessible for residents. To do so, the company creates high-performance, prefabricated assemblies that expedite the building process.

Advanced manufacturers in New Mexico are addressing workforce and housing needs.

By Val Hunt Beerbower on November 27, 2024

Livability: New Mexico

Advanced manufacturers in New Mexico are leveraging the state’s resources and talent pool to drive innovation.

As a result, creative solutions are arising for modern-day challenges. For example, Albuquerque startup Build With Robots is tackling workforce demands, while B.PUBLIC Prefab in Santa Fe is developing affordable housing options.

Advocating for Affordable Housing

New Mexico’s growing popularity presents an opportunity to develop innovative affordable housing models for its expanding population. Fortunately, one woman-owned, public-benefit corporation has stepped up to the challenge.

B.PUBLIC Prefab launched in 2019 to make climate-friendly homes more accessible for residents. To do so, the company creates high-performance, prefabricated assemblies that expedite the building process.

“We believe that the shortage in housing is a humanitarian crisis,” says Edie Dillman, CEO and co-founder of B.PUBLIC Prefab. “Building faster, better, responsive housing to address specific and growing needs is urgent, and all effort should be made to create access and affordability.”

Dillman’s company generates insulated wall panels that are assembled into houses and low-rise multifamily buildings. The company also offers floor plans that developers or any potential homeowner can use to design a home.

In addition, the company launched a wall panel that meets the requirements for a single building material that provides all the structure, insulation, and air and weather barriers for the shell of any building from one to three stories high. Introduced at the International Builders’ Show in Las Vegas, this advance in the manufacturing process replaces the time-consuming steps of a site-built project into a single order, delivery and installation.

“Our little company was on the biggest stage for building materials, among 1,800 exhibitors and 76,000 attendees. We were the only company of our kind there and making a big splash,” Dillman says.

She credits collaborative efforts from public and private institutions in New Mexico with jump-starting companies like hers and ensuring businesses have the support they need to succeed. The Job Training Incentive Program, for instance, funds classroom and on-the-job training for newly created jobs in expanding or relocating businesses. The program reimburses 50% to 90% of employee wages, allowing companies like B.PUBLIC Prefab to pay new staff while they’re in training.

“We look to our local and state economic development departments for ideas, advisers, encouragement and opportunities, and we always get their support,” Dillman says. “Innovation and entrepreneurship are a part of the culture of New Mexico. People are very encouraging of new ideas and creating something unique here. We have also been very fortunate to have support from the state in many ways.”

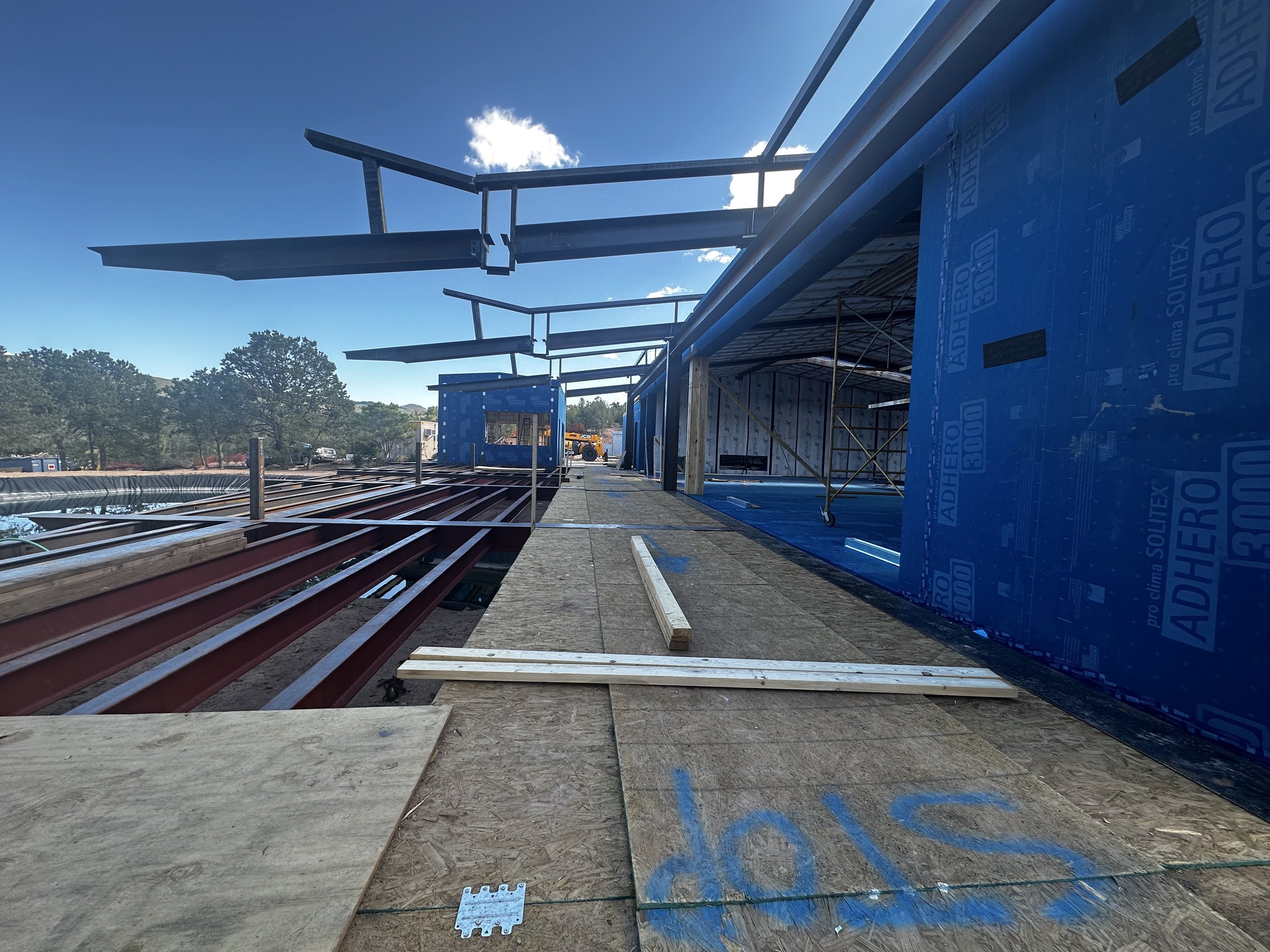

Santa Fe Institute to build lecture hall with eye on sustainability

B.PUBLIC Prefab produced sustainable components, such as floors, walls and roof, for the forum. These prefabricated materials act as "the thermal envelope for a building" and will use 90% less energy than other buildings like it, said Jonah Stanford, co-founder and chief technical officer of B.PUBLIC Prefab. This novel, and green, approach to building is one of the reasons B.PUBLIC Prefab was chosen to work on the project, Tom Easterson-Bond, the in-house architect for SFI, told the Journal.

Congratulations to an amazing team for a vision for building sustainably with building science at the center. Thank you to ABQ Journal and Jay Newton-Small for great coverage on this breaking news.

December 5, 2024

By Kevin Opsahl / Journal Staff Writer

For many physicists, everything in life is recycled: We are, after all, just once and future stardust. The Santa Fe Institute will be building on that idea quite literally this year, using recycled newspapers and prefab materials to construct a new lecture hall on its Miller Tesuque campus.

SFI, a highly regarded nonprofit studying science from a multidisciplinary viewpoint, partnered with Santa Fe’s B.PUBLIC Prefab on the Gurley Forum.

B.PUBLIC Prefab produced sustainable components, such as floors, walls and roof, for the forum. These prefabricated materials act as "the thermal envelope for a building" and will use 90% less energy than other buildings like it, said Jonah Stanford, co-founder and chief technical officer of B.PUBLIC Prefab. This novel, and green, approach to building is one of the reasons B.PUBLIC Prefab was chosen to work on the project, Tom Easterson-Bond, the in-house architect for SFI, told the Journal.

SFI approached his organization in the summer of 2022 to work on the 5,000-square-foot Gurley Forum, named after a longtime supporter. Before this, B.PUBLIC Prefab, founded in Santa Fe in 2019, had only built single family homes.

Stanford said it felt like a compliment for SFI to approach his organization to work with them on the forum. "We were definitely honored to be involved in (the project), just because the Santa Fe Institute does include some of the (most) creative, forward-thinking thinkers in the world," he said. "We are definitely in sync in terms of thinking long term around our community and our environment."

Albuquerque-based StoneBridge Construction and Design was tapped as the general contractor on the project. "B.PUBLIC and StoneBridge Construction and Design ... have done an exceptional job helping to bring a complicated narrative project to life," Easterson-Bond said.

Gilbert Almager, owner of StoneBridge Construction and Design, complimented the forum for its "unique look" and sustainable materials.

"I am very excited," he said. "We're getting closer and closer (to completion). It's going well."

Janet Gunn, vice president for administration at SFI, said the institute made a choice early on in the project to find local builders to work with them.

"We felt it would actually make the project come together in a smooth and seamless way, and it did," Gunn said.

The forum, which began construction in August and is expected to be complete in early 2025, will not be open to the public.

SFI, founded in 1984, has long studied cross-disciplinary science on its Cowan Campus in Santa Fe and has more recently been adding programs to its Miller Campus ever since it was gifted to the institute in 2012. The expansion of programming and need for more meeting space on the campus spurred the need for the Gurley Forum, Gunn said.

"You're not going to feel hot and stuffy" inside the forum, Stanford said.

Offsite Builder covers B.PUBLIC Builder Training

CEO and Co-Founder Edie Dillman says that the company has a strong commitment to the sharing of knowledge. “We focus on education that supports a builder’s evolution to hybrid site construction, assisted by offsite; on owner education about sustainability and performance; and on helping architects evolve their practice to higher code [requirements], lower carbon impacts and [greater use of] technology.”

Hands-On Training

Heather Wallace Featured in Offsite Builder

December 2, 2024

B.Public Prefab understands that trained installers are key to expanding its market, as well as the market for other prefab solutions.

The saying, “knowledge itself is power” is generally attributed to English philosopher Sir Francis Bacon. The phrase stemmed from his belief that knowledge provides something greater than physical strength — it enables people to make informed decisions based on data, resulting in proficient problem solvers.

Knowledge, however, is really only powerful if it’s shared.

That’s certainly the belief of B.Public Prefab, a New Mexico-based manufacturer of high-performance prefabricated homes that meet Passive House standards.

CEO and Co-Founder Edie Dillman says that the company has a strong commitment to the sharing of knowledge. “We focus on education that supports a builder’s evolution to hybrid site construction, assisted by offsite; on owner education about sustainability and performance; and on helping architects evolve their practice to higher code [requirements], lower carbon impacts and [greater use of] technology.”

Currently, B.Public operates with a distributed manufacturing model, with five manufacturers across the US. It needs local, trained installers in those areas.

Hands On

To fulfill this need, B.Public regularly offers High Performance Prefab Installer Training events at their factory in Las Vegas, New Mexico. During the two-day training, participants are given an overview of the Passive House approach and the strategies and materials needed. Classes are taught in conjunction with 475 High Performance Building Supply, which sells mechanical and building envelope products, and ships across the US and Canada.

During the hands-on portion of the training, attendees practice taping and sealing with B.Public’s choice of air and weather sealing products from Pro Clima, an international company focused on air tightness and vapor control.

B.Public CTO and Co-Founder Jonah Stafford (AIA), one of the first US design professionals trained in the Passive House standard, educates participants on how to successfully work with the company — from workflows to site prep considerations, to understanding how to properly receive and store prefabricated building assemblies. For traditional on-site builders, this instruction provides insights into the differences involved in building with airtight, offsite components.

On day two of the training, attendees learn the rigging, hoisting and safety standards surrounding crane coordination and signaling. Participants then practice signaling with a crane operator as they rig, square, and attach wall and roof panels. The day ends with a short ceremony where graduates are recognized as trained installers for B.Public Prefab products.

Industry Benefits

The company consistently uses field feedback from trainees for constant improvement in their training materials. For instance, father-son team, Eli and Chris Waterhouse, experienced builders based in Colorado, attended a recent training session after completing a challenging, highly custom build using B.Public components. Participants were able to glean best practices from the duo as a result of their own successes and failures.

So, is the training a marketing ploy? Yes, and no. Most builders who participate in B.Public’s Installer Training do not have projects scheduled with the company. Instead, they are interested in advancing opportunities and being a part of a community of builders.

“We hope that all of these builders [who attend our trainings] will build with us, but that isn’t a requirement or a measure of our success,” says Dillman. “We are passionate about what we know and have developed. The sharing of knowledge is a part of our success metric.”

The training is also applicable to set and stitch crews for other prefab high-performance envelope systems. In fact, B.Public has convened a consortium of wood-based panelizers across North America to develop collaborative opportunities and shared resources to move the offsite market forward.

Design Education

A good training program also identifies the holes and biggest recurring challenges. And with the offsite industry, many times those challenges revolve around gaps in architectural practice, and architects’ exposure to new building methods.

“Traditionally, air tightness in the Passive House method is the thing that ends up costing the most and is almost always underbuilt by architects,” says JD Scott, B.Public’s lead architect. “As a licensed architect, I appreciate the power of formal design education,” he says. “However, architecture schools have traditionally incentivized practices that can conflict with high-performance building principles.”

He notes that design education rewards students who break with conventions. It encourages them to constantly “reinvent the wheel” on projects, which means that graduates enter professional practice with the notion that every project must somehow be groundbreaking or complex. “As a result, architects often have an aversion to working within parameters and systems they perceive to be limiting to their authenticity as designers.”

However, Scott has not found parameters to be limiting at all.

“Hard parameters drive creativity and innovation on projects. When I work with my own clients — most of whom are on tight budgets — I let them know that they can invest in complexity for a single, special moment (a large set of windows, for instance), but that the rest of the project should be straightforward. I like to think that we are imparting this approach onto other architects as well.”

In addition to its Installer Training, B.Public offers an architect training program. It also presents to architects and designers at conferences and workshops, and holds regular “Lunch and Learn” events for architects, builders, developers and real estate professionals to gather together and explore innovative technologies, strategies and solutions for the future of the building industry.

“We hope to inspire people to take action with what we offer,” says Dillman. “New construction is challenging for all parties — it makes sense to us that everyone is more resilient when they know what impact they can affect.”

For upcoming events and webinars with B.Public Prefab visit www.bpublicprefab.com/-events-webinars.

B.PUBLIC At Build Show Live

We attended Build Show LIVE in Austin, Texas and had a blast partnering with Retrotec and joining them in their booth at the show.

We attended Build Show LIVE in Austin, Texas and had a blast partnering with Retrotec and joining them in their booth at the show.

Builders, Craftsmen and Innovators Unite: Build Show LIVE Sparks a Movement in Building Science

AUSTIN, TX / ACCESSWIRE / November 13, 2024

Build Show LIVE, the brand-new tradeshow held last week in the heart of Austin, was the launch of a transformative movement, bringing together passionate builders, remodelers, architects and manufacturers from 47 states and nine countries, who are committed to elevating the future of residential construction.

Throughout three dynamic days, more than 300 VIPs and thousands of construction professionals engaged in expert-led workshops, live product demonstrations, exclusive home tours and networking opportunities with manufacturers showcasing a range of the most advanced and high-performance building products. A highlight for many, the off-site home tour experience led attendees through a powerful immersion into cutting-edge building science and craftsmanship outside of the expo hall and into real-life applications. The tour highlighted an in-progress Risinger Build home under construction and a finished masterpiece by celebrity building expert Matt Risinger. "The learning experience was invaluable," one attendee notes. "Hearing from Matt himself and seeing how each product played a role in the overall design really reinforced the importance of detail and quality."

Build Show LIVE created a platform for quality conversations and meaningful connections. Exhibitors experienced record-high engagement, connecting with a targeted audience of custom home builders, general contractors and remodelers eager to learn how to build better and innovate. "The caliber of attendees was incredible, with builders looking to solve real-world challenges with real solutions," says an exhibitor. "This is exactly the community we want to be part of."

Builders who attended Build Show LIVE share a vision of constructing quality homes that goes beyond the ordinary. These professionals show exemplary focus on high-performance, energy-efficient products and are meticulous about detail, design and above all, quality. For them, the event represented a deeper commitment to reshaping industry standards and an ongoing dedication to the growing new home market.

"The launch of Build Show LIVE showcased our unparalleled expertise in building industry marketplaces, seamlessly complemented by The Build Show's exceptional content creation and deep knowledge of building science," shares Kevin Thornton, Senior Vice President of Infrastructure and Construction at Informa Markets. "The collaboration resulted in a highly engaged, purpose-driven experience where construction professionals could come together to gain the knowledge, skills and resources needed to perfect their building techniques."

Build Show LIVE fuels a movement that emphasizes quality, craftsmanship and environmental responsibility. The community is united by a shared mission to Know Better. Build Better.™ Builders, remodelers and contractors left inspired, equipped and ready to apply what they learned, whether through innovative products, the latest building science practices or invaluable connections with like-minded peers and mentors.

"Build Show LIVE represents a groundbreaking evolution in how the construction industry engages with content, expert builders and craftspeople," shares Matt Risinger, Founder of The Build Show. "It lays an essential foundation in the South, offering building professionals the resources and insights needed to construct high performance healthy homes."

In the words of another exhibitor: "Build Show LIVE is a testament to what is possible when passionate people come together to drive change in our industry."

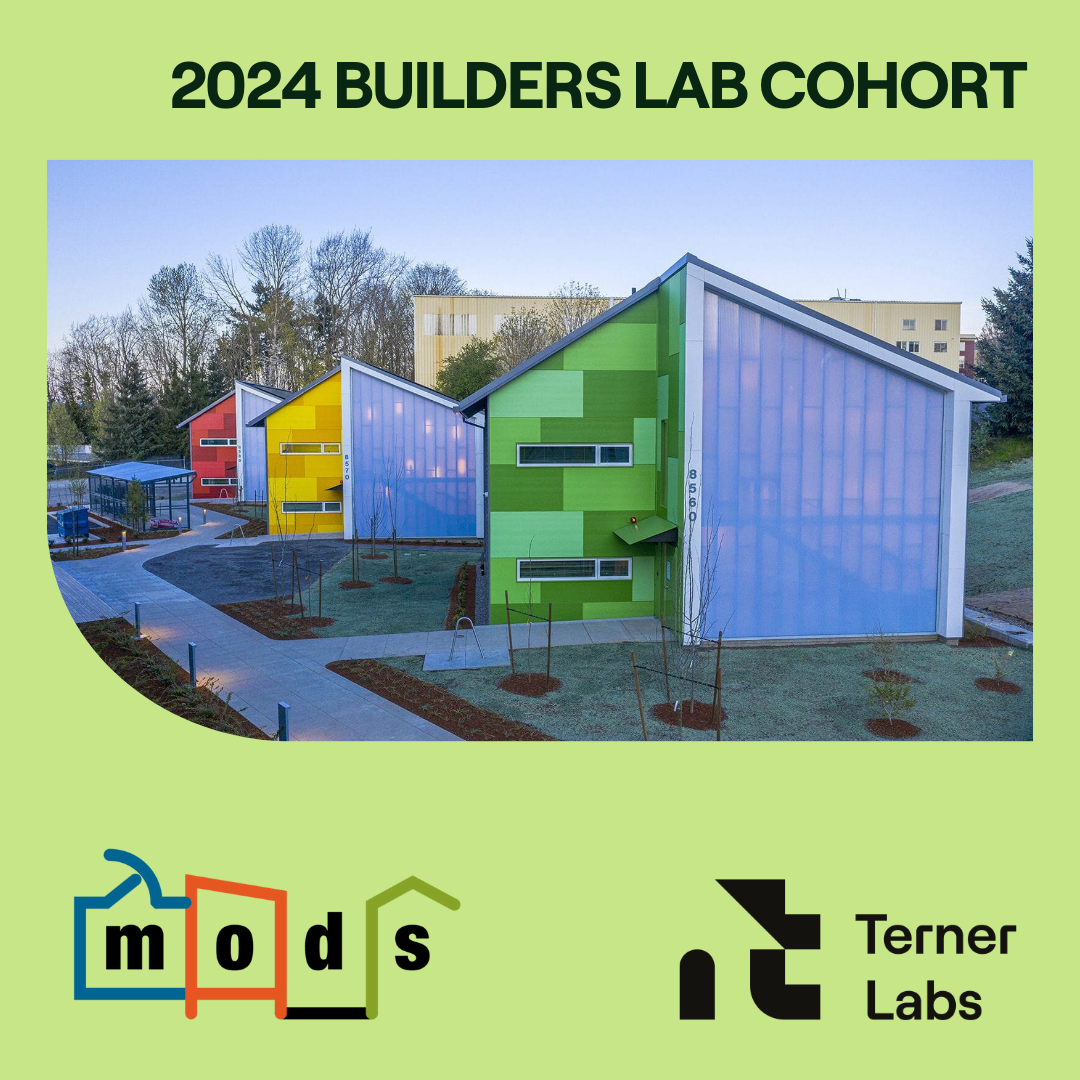

Introducing the 2024 Builders Lab Cohort

Today, Terner Labs announced the inaugural cohort of ventures for its Builders Lab. The Builders Lab is an accelerator program that works with innovators in architecture, engineering, construction and hardware to scale efficient, cost-effective and sustainable methods of housing delivery across the U.S.

Article from Terner Labs

Terner Labs announces inaugural Builders Lab cohort and strategic partnerships to build housing better

Today, Terner Labs announced the inaugural cohort of ventures for its Builders Lab. The Builders Lab is an accelerator program that works with innovators in architecture, engineering, construction and hardware to scale efficient, cost-effective and sustainable methods of housing delivery across the U.S.

Terner Labs also announced that industry leaders Eden Housing, Hilti, SCB, Skidmore, Owings & Merrill (SOM), and Suffolk Construction have joined the Builders Lab as strategic partners. Their institutional expertise from diverse standpoints within the housing, construction and architecture ecosystem will support cohort members as they seek to scale and advance industry-wide change.

Terner Labs created the Builders Lab to address challenges faced by companies pioneering new approaches for building housing within the traditional entrepreneurial ecosystem: product-market fit, financing,and a complex regulatory landscape. But the ongoing housing crisis and growing focus on climate impacts make innovation in the sector a necessity.

It has become increasingly clear that our housing delivery system needs to significantly increase its scale and sustainability, and innovators must play a crucial role.

Ben Metcalf, CEO of Terner Labs

The program builds on the success of the Housing Venture Lab, which has supported more than 20 ventures advancing affordability, sustainability and equity in housing since 2019.

The Builders Lab will support a group of geographically diverse early- to middle-stage companies over nine months, offering coaching, curated curriculum, visibility to Terner Labs’ network of regulators and policymakers across government, and relationship-building opportunities with strategic partners and advisors. The programs will also host an international study tour to deepen cohort members’ familiarity with mature industrialized construction ecosystems.

This year’s cohort includes six trailblazing companies representing a diversity of approaches to industrialized construction across the United States: Villa, B.PUBLIC Prefab, MODS PDX, Cloud Apartments, Cycle Retrotech, and Hydronic Shell. Each brings unique potential for growing innovation in the architecture, engineering and construction sector.

“We are excited to work with our strategic partners to support these industry pioneers, and together we hope to drive meaningful change toward a more sustainable and accessible housing future,” said Ben White, Director of the Builders Lab.

“The Builders Lab will accelerate the delivery of innovative solutions to our housing crisis, helping make it more available, affordable and sustainable,” said Eden Housing’s President Linda Mandolini. “We believe everyone deserves a safe, affordable and healthy place to call home, and this collaboration will help create meaningful change for countless individuals and families.”

“At Hilti, we're committed to driving innovation in the construction industry. The Builders Lab program aligns perfectly with our vision of creating more productive, safer and more sustainable construction. We're excited to partner with Terner Labs and support these promising startups as they work to revolutionize housing delivery across the U.S.” said Antonia Soler-Blasco, Head of Hilti Venture.

“As an urban architecture firm, SCB is deeply invested in providing design solutions for housing that prioritize affordability and sustainability and enhance community well-being. We are excited to collaborate with Terner Labs on this important initiative and look forward to engaging with the innovative companies in the Builders Lab cohort. Together, we aim to advance techniques that will provide a measurable impact on the delivery of housing for communities across the country,” said Strachan Forgan, AIA, SCB Principal and Executive Director.

"We are proud to support Terner Labs' mission to pioneer new approaches to building housing," said SOM Architect Lisa Follman. "We look forward to leveraging our expertise in architecture, sustainable engineering, structural engineering, and urban planning as a strategic Partner to the inaugural cohort of the Builders Lab and extending our legacy of catalyzing policies that can enable housing innovations."

"Together, by pushing the boundaries of what's possible, we can build a future where sustainable and accessible housing is not just an ambition, but a reality for all. Suffolk is excited to form powerful partnerships, and leverage innovations to build not only faster and more affordably, but also smarter and more sustainably. Through collaboration, we are paving the way for a new era of housing that unites expertise with cutting-edge tools to transform communities for generations to come,” said Karri Novak, California Project Development Vice President at Suffolk.

The Builders Lab is a program of Terner Labs, an organization founded out of the Terner Center for Housing Innovation at the University of California, Berkeley. The Builders Lab has received generous support from the Chan Zuckerberg Initiative and JPMorgan Chase & Co, along with a growing group of senior-level strategic advisors and government supporters. To get updates about the Builders Lab and other initiatives, sign up for the Terner Labs newsletter and follow Terner Labs on LinkedIn.

More about the Builders Lab cohort:

B.PUBLIC Prefab

B.PUBLIC is a sustainability-focused manufacturer of panelized building systems based in Santa Fe, New Mexico. B.PUBLIC is centered on advanced construction methods that are better for homebuilders, homeowners, and the planet. Their product design, materials specs, and industry training programming equip builders to implement sustainable building practices, counteract the rapidly shrinking construction workforce, speed up the adoption of carbon-appropriate materials, off-site construction, and NetZero building performance. This team of architects, building scientists, tradespeople, and innovators is addressing housing, climate, and labor crises through off-site construction.

Cloud Apartments

San Francisco-based Cloud Apartments is a data-driven developer platform transforming the construction of multi-family housing into a repeatable, scaleable, and profitable process through a patented modular product and network of certified partners. Cloud leverages its innovation and business model to reduce the cost of construction, enabling cities to increase housing supply quickly & efficiently.

Cycle Retrotech

Cycle Retrotech, based in Brooklyn, NY, provides integrated energy and electrification retrofit solutions for multi-family buildings. Leveraging the products of an array of manufacturing partners, Cycle designs, plans and manages the retrofit process from building assessment through design, fabrication, installation, and monitoring. Their turnkey, replicable approach aims to meet the large and growing demand for decarbonization retrofits.

Hydronic Shell

Hydronic Shell is a hardware technology provider based in New York, NY. They have patented a componentized roof- and facade-mounted HVAC system to unlock deep energy retrofit and electrification feasibility for multifamily housing. Their system includes all elements necessary to deliver complete heating, cooling, and ventilation to each unit in tall residential buildings, and by enclosing the components within the new facade, they avoid displacing residents during installation.

MODS PDX

MODS PDX is a leading modular builder in the Pacific Northwest, manufacturing volumetric housing units using mass plywood panels, an innovative mass timber product. The company has worked with a diverse array of customers including developers building workforce housing and cities building temporary housing for the unhoused. Operating in Oregon, Washington, Idaho, California and Nevada, MODS PDX’s leadership brings 15 years of experience in modular design and delivery to their efforts to address the housing crisis.

Villa

Villa, based in San Francisco, is a next-generation homebuilding platform that applies modern offsite construction methods and technology to efficiently build much-needed housing in infill locations. Villa’s mission is to be the easiest, fastest, and most cost-efficient way to build quality homes. By partnering with a wide network of offsite housing manufacturers, Villa acts as a demand aggregation and fulfillment partner that provides a seamless customer experience through discovery, feasibility, permitting, installation (project management and general contracting), and post-completion service. Villa is currently a leading builder of ADUs throughout California and is expanding into building primary homes across a variety of ‘missing middle’ typologies.

Shape Architecture and B.PUBLIC Prefab Announce Exciting Design Collaboration for High-Performance Homes

Shape Architecture and B.PUBLIC Prefab are thrilled to announce their trailblazing design collaboration, leveraging their combined expertise to deliver a series of high-performance, high-quality, and delightful home plans. This partnership, marked by innovation and sustainability, will see the monthly release of new signature home plans available for licensing through the remainder of 2024.

Innovative Partnership to Release New Signature Home Plans Monthly Through 2024

DENVER, CO, September 9, 2024

Shape Architecture and B.PUBLIC Prefab are thrilled to announce their trailblazing design collaboration, leveraging their combined expertise to deliver a series of high-performance, high-quality, and delightful home plans. This partnership, marked by innovation and sustainability, will see the monthly release of new signature home plans available for licensing through the remainder of 2024. These two leading companies in Passive House join forces to offer homeowners and developers beautifully designed homes to be built with B.PUBLIC’s panels for healthy, low-energy, low-carbon long-term sustainability.

Shape Architecture, renowned for its sustainable architecture, building science expertise, and compelling, site-responsive designs, has joined forces with B.PUBLIC Prefab, a leader in high-performance prefabricated building solutions. This collaboration merges Shape Architecture's award-winning design approach with B.PUBLIC Prefab's cutting-edge prefab panelized construction, resulting in homes that are visually striking and built to the highest standards of performance and sustainability.

Each home plan, meticulously crafted by Shape Architecture and constructed with B.PUBLIC Prefab’s wall/roof/floor panels, embodies the future of residential living. These plans emphasize energy efficiency, durability, and modern design, setting a new benchmark for high-performance homes.

Key Details of the Collaboration

Monthly Releases: Starting this September, a new signature home plan will be unveiled, providing a diverse range of options for prospective homeowners and builders.

High-Performance Focus: Each design is crafted to meet the highest standards of energy efficiency and environmental responsibility, leveraging B.PUBLIC Prefab’s advanced prefab technology.

Ongoing Partnership: This initiative reflects a commitment to ongoing innovation and collaboration, with plans to continue releasing new designs throughout 2024.

“We are excited to embark on this journey with B.PUBLIC Prefab,” said Steve Scribner, Principal at Shape Architecture. “Our shared vision for high-performance living and commitment to sustainable design make this partnership a natural fit. Together, we are setting new standards for what is possible in modern home design.”

“Partnering with Shape Architecture allows us to showcase their beautiful work and offer a Shape original,” adds Charlotte Lagarde, COO at B.PUBLIC Prefab. “We have been fans of Shape for many years. Both teams have worked together and have the utmost respect and joy in collaborating. This is going to be fun for our clients to work with these great professionals.”

The first of these signature home plans will be revealed on September 14th from the Colorado Green Building Guild’s Green Home tour, with subsequent releases scheduled for the remainder of 2024. Builders, developers, and homeowners interested in licensing these cutting-edge designs are encouraged to visit www.bpublicprefab.com/collabs for more information and to explore the exciting new offerings.

The Cascade House (named after the dramatic and serene landscape of Northern Washington), is designed to be compact and efficient while expansive and flexible. At just 1,660 sf, it includes three bedrooms and a generous common kitchen/ living/ dining space, as well as a small home office, mudroom, laundry room, and pantry. A screened-in porch off the dining room and generous covered patio expands the useable space significantly, helping integrate the simple footprint into the landscape and enabling a truly indoor-outdoor lifestyle. Small on cost and square footage, big on natural light, flexibility, efficiency, and connection to the land!

About Shape Architecture

Established in 2016, Shape Architecture Studio is an award-winning, values-driven company committed to pushing the limits of sustainability and design. They are passionate about creating positive impact in communities across the country, through attainable, site specific architecture that embraces the passive house standard.

At Shape, sustainability isn’t just a buzzword; it’s a guiding principle. This means using energy modeling and building science to drive energy use to the lowest levels possible. And importantly, they strive to do this at competitive price points - it is their mission to make truly sustainable architecture accessible to everyone, without compromising on aesthetics. They work hard to create delightful, site-specific work that is appealing and approachable for people of all tastes and preferences - by making Passive house levels of sustainability attractive and affordable to a wider population, they are helping drive demand for better buildings, and together with B.PUBLIC are excited to move the needle toward a lower-carbon society. SHAPE was announced Winner of AIA Colorado “Young Firm of the Year 2024 on September 12, 2024.

For more information, visit www.shapearchitect.com

About B.PUBLIC Prefab

B.PUBLIC Prefab is a leader in high-performance prefab construction, specializing in creating sustainable and efficient building solutions. With a commitment to quality and innovation, B.PUBLIC Prefab transforms the way homes are designed and built, offering a range of prefab options that meet the highest performance standards, including Passive House. B.PUBLIC Prefab launched the COLLABS portfolio of pre-designed home plans in 2023 with HereAbout Homes and will continue to partner with leading architects to offer a wide range of home plans from ADUs to TownHomes. B.PUBLIC is a woman-owned public benefit corporation based in New Mexico, working across the US with leading green architects and builders for new construction. For more information, visit bpublicprefab.com.

About Collabs

B.PUBLIC Collaborations (Collabs) brings together leading architects and the B.PUBLIC studio to offer clients beautiful and deeply sustainable pre-designed plans for new construction. As a prefab manufacturer focused on high-performance sustainable materials, B.PUBLIC supplies prefab structures to Architects and Builders across the US. Their innovative design and fabrication support the speed and accuracy of craftsman construction to custom projects. COLLABS is an opportunity for customers to access world-class architectural design and sustainable construction through a beautifully curated collection of home plans. Design collaborations have a long and exciting history from leading fashion brands, artists, celebrities, and designers - B.PUBLIC’s COLLABS is unique as it is a way for the mission-centered corporation to make exceptional architectural designs and green excellence an accessible option for individuals and developers. COLLABS is a program that showcases timeless designs and forward-thinking architects that B.PUBLIC is proud to celebrate.

What is Passive House?

“Passive House design empowers us to manage moisture, thermal transfer, air, and sunlight to create comfortable, healthy, super-efficient buildings. The “classic five” Passive House design principles—continuous insulation, thermal bridge-free design, airtight construction, high performance windows and doors, and filtered fresh air with heat recovery—are joined by the principles of shading, daylighting and solar gain, efficient water heating and distribution, moisture management in assemblies, and building orientation to create durable, high performance buildings where people can thrive.

The Passive House approach empowers us to build better. It creates durable, resilient buildings that slash heating energy use by as much as 90% and dramatically reduce operational carbon emissions. Passive House design tools and methods make these energy performance gains both cost-effective and predictable. You know what performance to expect with a certified Passive House.

Most importantly, Passive House buildings create healthy, comfortable, and quiet interior environments, full of clean, filtered fresh air.”