New Off-Site Construction Standards: Codes Working Group Brief

This work incorporates valuable elements and insights from members of the ABC Collaborative Working Group on Codes, Standards, Permitting, Testing, and Accreditation.

New off-site construction standards:

Potential & implications of ICC/MBI 1200 and 1205 for advanced building construction

It is no secret that the US construction industry faces a confluence of challenges, including stagnant productivity, costly delays due to extended labor shortage and supply chain variability, and persistent hesitation towards innovation. Advanced building construction (ABC) approaches, such as highperformance prefabricated off-site construction, offer a promising solution to these challenges and help invigorate the construction industry while providing a spectrum of environmental and economic benefits. Off-site construction can provide superior energy efficiency, tighter building envelopes, carbon and waste reduction, significant cost efficiencies, buffering of supply chain delays, and attractive employment for a new generation of the construction workforce, among other benefits.

Benefits of Off-Site Construction Depend on Code Approval

Accelerated construction timelines and their associated cost savings are often highlighted by fabricators and suppliers as key benefits of prefabricated systems. Off-site construction processes allow multiple building components to be constructed simultaneously while protecting the components and workers from weather-related and other risks. As a result, off-site construction can yield 50% faster construction timelines with higher quality control — welcome improvements in an industry (dominated by conventional building practices) where some 75% of projects are late, over budget, or both. Prefabricated buildings are an attractive option for developing new construction projects because of their potential advantages over conventional construction. However, the economic and time-saving benefits of off-site construction quickly diminish if states and cities do not have efficient mechanisms to determine the compliance of offsite construction with applicable building code requirements. If code officials are unfamiliar with the methodology and terminology for approving closed prefabricated panels or modules at the site, projects using off-site construction can be delayed, while the backlogs of permits, inspections, and compliance paperwork burden local officials. Projects may also be rejected outright. Ultimately, these challenges may deter builders from choosing an otherwise attractive pathway to new construction. The current code landscape and regulatory barriers reflect the construction industry’s aversion to change. However, the transformation of building code paradigms can unlock more streamlined and efficient approaches to construction.

Fragmented Landscape: Codes Can Hinder or Help Adoption of Off-Site Construction

In states without clear code compliance pathways for off-site construction inspections and approvals, off-site projects can face lengthy delays, limiting the realization of off-site construction’s advantages. In states that do have off-site code compliance programs, outdated regulations, and nuances bring in confusion, unnecessary delays, and added costs, thus preventing the widespread adoption of off-site construction practices and limiting manufacturers to jurisdictions with familiar local code officials. This is partly a result of the fragmented and complex building code landscape in the United States, where building code requirements often differ from jurisdiction to jurisdiction and state to state.

In the United States, states or localities that adopt and enforce codes are referred to as authorities having jurisdiction (AHJs). AHJs often rely on model building codes developed by the International Code Council (ICC) and known as the International Codes (I-Codes). The I-Codes include the International Residential Code (IRC) and International Building Code (IBC), in addition to energy, zoning, and fire codes. The IRC and IBC are published on three-year cycles, and states and localities retain the authority to choose the version of the code to adopt through legislative or regulatory action.

States and localities typically base their adopted codes on a version of the IBC and IRC with various amendments, differing degrees of enforcement, and exceptions or additions. They adopt and update their building and residential codes independently of one another — every six to nine years on average — adding another layer of fragmentation.

Even within a state or locality, the codes for different construction types may be based on model codes from different years. For example, Utah adopted and enforces its commercial building code based on the 2018 version of the IBC, while residences are held to codes based on a version of the 2014 IRC. In Tennessee, commercial buildings are held to the 2012 IBC, while residences must meet requirements based on the 2018 IRC. While most AHJs develop their respective building and residential codes by slightly modifying the I-Codes, several US states have not adopted an IBC or IRC statewide. This allows municipalities to govern residential and building code adoption, mandates, and enforcement.

The outcome is a building code landscape that is highly fragmented, ranging from enforced statewide mandates or no building codes to specific exclusions and odd nuances. Colorado, which does not have a statewide code, leaves code adoption, compliance, and enforcement to its 59 permitting municipalities. Of these, 15 have no residential or building code requirements, and the remaining have adopted recent codes, resulting in jurisdictions with stringent building codes next to neighbors that have none. Although Iowa does not have a designated or adopted statewide building code, state government buildings must comply with the 2015 IBC. Maine took a different approach when it adopted the 2015 IBC and IRC statewide but allowed towns with fewer than 4,000 residents to choose to adopt and enforce codes independently. In New York State, the 2018 IBC and IRC are mandated and enforced at the state level, barring New York City, where different building codes apply. In short, the basis for and enforcement of building and residential codes and enforcement is fragmented on multiple scales.

One common thread across the fragmented code landscape is that building codes and industry standards are generally written from the perspective of site-built construction. Nevertheless, permanent prefabricated construction must comply with these local building codes.

Notably, off-site construction can refer to manufactured homes (historically called mobile homes) as well as permanent prefabricated modular or panelized construction. While manufactured and modular or panelized homes are prefabricated at off-site locations, they are regulated by different codes. Manufactured housing is regulated at the federal level by Manufactured Home Construction and Safety Standards administered by the US Department of Housing and Urban Development (HUD). The HUD code first came into effect in 1976, and HUD last updated its energy provisions for manufactured housing in 1994, although new standards are set to go in effect later this year. (Manufactured housing built before 1976, properly referred to as mobile homes, does not comply with the HUD code.)

In contrast, permanent prefabricated construction is held to the same local residential and building codes as conventionally constructed buildings. While manufactured housing is an important option for homeownership for nearly 22 million Americans, the remainder of this brief focuses on navigating codes for permanent prefabricated construction.

The IBC and IRC do not mention the term “modular,” but, again, all permanent prefabricated construction projects must adhere to local building and residential codes, introducing layers of complexity and barriers for the offsite construction industry. Unlike the federal HUD code that guides manufactured housing code compliance nationwide, there is no national code for modular construction at this time.

By definition, prefabricated buildings comprise volumetric modules or panelized systems constructed off-site and transported to and installed or assembled at their final destination. This introduces challenges for onsite inspections when the wall assemblies are already closed before they reach the site (closed construction). For example, a local official may need to inspect the insulation within a wall, but the wall system is closed at the manufacturing facility and the local inspection official lacks a mechanism to inspect and approve what they cannot see once the system arrives at the job site. This often leads to delays in inspection approval or, perhaps, failure of code inspection altogether. Additionally, this fragmentation increases barriers to market entry for innovative ABC solutions such as energy-efficient podded HVAC units, highly insulative technologies, or dynamic windows to satisfy code compliance standards across a multitude of jurisdictions. Navigating fragmented building codes and compliance thus deters ABC technologies’ widespread adoption and is a barrier to their development as it represents a potentially insurmountable cost for seed-level technology that offers superior energy efficiency, performance, or durability.

“Silence in the code is not an exemption from the code.”

-Modular Building Institute (MBI)

Just as the adoption of building codes varies from state to state, the regulation of off-site construction also differs, introducing an additional level of complex fragmentation for off-site builders, inspection officials, and end-users. While 39 US states have state-level regulatory offices that oversee off-site construction, the rules for each of these programs vary significantly. some cover only commercial or residential projects, others include only modular or panelized systems. Additionally, while some allow the use of third parties for plan review and inspection, others carry these out in-house. There is an additional level of inconsistency related to the department responsible for overseeing these programs in each state. In Illinois, the Department of Public Health holds the statewide regulatory authority over off-site construction. However, in Maryland, the Department of Labor regulates off-site construction. In the 11 states that do not have state-level off-site compliance programs, the entire regulation is the responsibility of local officials who often lack the expertise, resources, terminology, or framework to inspect and approve off-site projects.

Lack of consistency in regulating off-site construction undermines the inherent efficiencies of these approaches. If a manufacturer expands across state lines or localities, it may need to alter its compliance processes to accommodate jurisdictional differences, counteracting the benefits of having a highly replicable process. While states without off-site regulatory compliance frameworks stand to benefit from implementing a mechanism to inspect and approve off-site projects, the entire industry would gain from consistent and uniform processes across state lines.

The Solution: Introducing ICC/MBI Standards 1200 and 1205

Given the complexity of code adoption processes, varying degrees of code implementation and enforcement, and silence from the IBC and IRC on off-site construction, off-site manufacturers, contractors, and officials plainly need clearer compliance pathways. To fulfill this need, the ICC and Modular Building Institute (MBI) created the 2021 ICC/MBI Off-Site Construction Standards 1200 and 1205. Standard 1200 governs the planning, design, fabrication, and assembly, while Standard 1205 covers the inspection and regulatory compliance of off-site construction. The first edition of ICC/MBI Standards 1200 and 1205 was developed by the ICC/MBI Off-Site and Modular Construction Standard Consensus Committee (IS-OSMC) in compliance with the American National Standards Institute (ANSI)-approved ICC Consensus Procedures. The ISOSMC comprises 15 representatives from nine stakeholder categories (manufacturer, builder, standards promulgator/ testing laboratory, user, utility, consumer, public segment, government regulator, and insurance) to ensure adequate consensus and fulfillment of ANSI requirements. While the effort to advocate for the inclusion of Standards 1200 and 1205 into the 2024 IBC was unsuccessful, they are readily available for immediate adoption and use by jurisdictions.

“Most folks would say codes are not the most exciting topic, but I see them as the intersection of a variety of things—it’s the pathway to unlocking off-site construction, affordable housing, resiliency, sustainability, and bringing those pieces together.”

-Ryan Colker, Director of Innovation, International Code Council (2020)

The adoption of these standards serves as a tool to support the promise of off-site construction on two key scales: individual jurisdictions and across jurisdictions with widespread adoption. In individual jurisdictions that adopt the standards, off-site construction has greater potential to ease the ongoing affordable housing crisis faced by many regions through efficient and fast construction of high quality buildings at lower cost. On a large scale, widespread adoption of the standards effectively reduces the burden of navigating the current patchwork of regional regulations and promotes industry standardization, allowing manufacturers to operate more efficiently and expand their markets.

ICC/MBI 1200-2021 Standard for OffSite Construction: Planning, Design, Fabrication, and Assembly

ICC/MBI Standard 1200 provides guidance and insight for the planning and preparation requirements of offsite construction projects. Standard 1200 outlines the appropriate roles for architects, modular manufacturers, construction managers, and general contractors; planning requirements for the location of the manufacturing plant relative to the final construction site; and material procurement and lead times. In addition, Standard 1200 includes the requirements for maintaining a controlled manufacturing environment and material protection, effective supply chain integration, structural versus nonstructural modular, fabrication process, and on-site assembly. The Standard is available for adoption by AHJs and sets forth a framework to allow modules to comply with local building codes while providing a clear structure of the required roles, responsibilities, and necessary documentation at each step. The requirements of Standard 1200 establish off-site construction code compliance consistent with the scope of the I-Codes to protect public health, safety, and welfare, without unnecessarily increasing construction costs, and support the use of new materials, products, and methods.

ICC/MBI 1205-2021 Standard for OffSite Construction: Inspection and Regulatory Compliance

ICC/MBI Standard 1205 addresses the societal and industry challenges in the inspection and regulatory compliance of off-site residential and commercial building components. Standard 1205 also provides a framework for permitting, inspections during assembly at the manufacturing site, final inspections on-site, and third-party plan review and inspections. The roles and responsibilities of builders, state modular programs, and AHJs are outlined as well. Standard 1205 provides guidance for streamlining inspections and approvals through insignias, identification and data plates, implementation of quality control processes, and factory inspections, which are then followed up with on-site inspections at the final site. These procedures reduce the barriers for final on-site inspection processes and allow for faster construction timelines to realize the cost and time savings offered by off-site construction. In addition, they provide code officials and third-party inspectors a pathway to approve off-site construction projects.

Source: ICC/MBI Standard 1200; ICC/MBI Standard 1205.

To achieve the promise of off-site construction and a more efficient, sustainable, affordable, and innovative construction industry, effective code compliance mechanisms need to be identified and implemented. Collectively, Standards 1200 and 1205 set out a framework for the efficient and consistent approval of off-site construction projects, benefiting regulatory officials and inspectors, off-site manufacturers, and the localities where they are adopted. When Washington State adopted the third-party framework for off-site construction inspections from Standard 1205, its regulatory approval backlog was reduced from 20 weeks to three weeks, lowering the burden on local officials.

Clear mechanisms for consistent permitting, in-factory and on-site inspections, and approvals also benefit manufacturers by reducing delays and added costs. In Illinois, a developer of an apartment building cited an additional $10,000 cost per unit when navigating the state’s off-site code regulations, which required additional inspections for high wind load conditions — a vestigial compliance requirement from when the state was focused on regulating mobile homes. It may also result from lack of clear terminology: modular buildings are secured to permanent foundations, akin to conventionally built housing, whereas manufactured housing is secured to a steel chassis. The unnecessary regulatory burden and barriers to approving off-site projects can be alleviated by the adoption of Standards 1200 and 1205. This will also reduce costs for manufacturers, allowing units to be constructed at lower costs and with greater replicability across markets. In tandem, this can allow faster construction of affordable housing. Adopting the clear and consistent framework set forth by Standards 1200 and 1205 allows off-site construction a foothold to gain greater traction as a solution to some of the complex challenges faced by the construction industry and society at large.

States and jurisdictions can adopt ICC/MBI Standards 1200 and 1205 into their statewide or local code to help enable the benefits of off-site construction. The 11 states without off-site programs are especially well-positioned to capitalize on off-site construction. Off-site manufacturers in states with well-developed off-site programs, such as California, will also benefit from the consistency; they can readily expand to other areas with consistent off-site regulatory processes without investing supplemental time and resources to educate AHJs. However, due to the code development and adoption processes in the United States, the standards currently serve only as an available resource — they neither hold the weight of the code as law nor can they be enforced until they are adopted by local authorities. The current status of the standards allows states and jurisdictions to adopt the standards at their own discretion with amendments and control (The benefits and drawbacks of a national offsite code for modular and panelized construction will be analyzed in a forthcoming, complementary brief).

IRC and IBC Development and Adoption

As noted previously, the IBC and IRC are developed independently by the ICC on a three-year cycle. The ICC code development process includes three inclusive and transparent stages. In the first stage, the ICC issues a public call for code change proposals. The code proposals are then made available for public review through the ICC’s cloud-based program to allow for broad involvement and transparency.

The second stage involves direct feedback through committee action hearings where code development committees hear public input on the merits of including proposed changes in the next edition of the code. The code development committees presiding over the committee action hearings are open for anyone to apply to serve. The ICC appoints members to the committee based on application recommendations from the Codes and Standards Council. The committee represents various interest categories, such as government regulatory agencies, users, building owners, designers, insurance companies, private inspection agencies, academics, producers, builders, contractors, manufacturers, and distributors, to capture a diverse array of stakeholder input. The committee then votes to either approve, approve with modifications, or disapprove code change proposals. The code development committees’ actions are open to public comment, whereby any participant may challenge a committee’s actions. The code change proposals are then considered at public comment hearings and voted on by eligible voters defined as representatives of government agencies with no financial stake in the outcome and committed to protecting public health and safety.

The final stage follows eligible voters’ final consensus. The ICC Board validates and confirms the code changes, and a new edition of the IRC and IBC is finalized and published. The most recent editions are the 2021 I-Codes, including the IRC and IBC.

The ICC develops building codes through a governmental consensus process to safeguard public safety. Although updated versions of the IRC and IBC are published on three-year cycles, states and AHJs update their local codes independently and at their own discretion. The result is often outdated I-Codes across many states and a delayed trickle-down of building code provisions into state adoption and enforcement. The following section outlines the building code adoption process by states.

Code Adoption

The process whereby AHJs adopt codes occurs on varying timelines determined by the state legislature, government agency, building code board, or building code commission. How codes are adopted and the relationship between state and local-level action also varies. Codes can be adopted at the statewide level for application across the state, with local governments enforcing the code. In Maryland, the code adopted statewide can be exceeded by local regulations, whereas in Virginia, local authorities do not hold the power to amend the statewide code. Some states chose to identify a code as required only if a locality elected to adopt it, as Mississippi does. States may also leave the adoption and enforcement of codes entirely up to local jurisdictions, as highlighted by Colorado’s structure.

Once a new building code is selected, it is adopted through legislative or regulatory agency action. Legislative building code adoption occurs through a legislative body (state legislature, or city or county council) where the code is introduced and modified by applicable committees. At this stage, input and collaboration from external stakeholders and nontechnical groups is collated on the new code, and modifications are implemented. Regulatory action adoption involves executive branch agencies, building code boards, or building code commissions tasked with reviewing and adopting building codes. A typical regulatory action adoption process relies on an advisory board of appointed industry stakeholders — from design and construction professionals to code enforcement officials — to review the code and make recommendations. The advisory board’s recommendations are then publicly reviewed.

While most states base their building codes on a version of the IRC or IBC, they are often renamed with state-specific names to reflect the modifications. In Maine, the state’s building codes are based on the 2015 IRC and IBC and are referred to as Maine Uniform Building and Energy Codes (MEUBEC) to reflect the state-specific amendments. Utah and South Dakota, along with a few other states, use the legislative process. Most states, including California, Connecticut, and Florida, use regulatory agency actions to adopt new building codes.

Alternative Pathways to Code Adoption

While the ICC’s code development process updates the IRC and IBC every three years to reflect current best practices, the slow uptake of updated codes by states hinders the widespread adoption of ABC and other innovative technologies and practices. When considering the code adoption process from the perspective of off-site construction, progress is constrained by a myriad of factors: limited compliance approaches at the state level, lack of process and infrastructure in localities without statewide programs, and general unfamiliarity with the existing compliance mechanisms for modular construction and innovative technologies. As mentioned earlier, the IRC and IBC do not mention the word “modular,” leaving ambiguity around — and hampering the deployment of — off-site construction and its many potential benefits.

However, ICC/MBI Standards 1200 and 1205 for Off-Site Construction are available for adoption by states and AHJs independently of the IRC and IBC adoption cycles. The voluntary adoption of these standards would allow localities to efficiently deploy ABC practices at scale and unlock the benefits of off-site construction to reinvigorate the construction workforce, reduce waste, better address the affordable housing crisis, and enhance sustainability. Salt Lake City has implemented these standards.

2021 ICC/MBI Standards 1200 and 1205 in Action

In a unanimous vote by the city council, Salt Lake City became the first jurisdiction to adopt ICC/MBI Standards 1200 and 1205 for Off-Site Construction in March 2021.

Salt Lake City was the preferred location for the adoption of off-site construction standards due to three factors: absence of a statewide off-site program, existing regulatory barriers for code officials in the city’s jurisdiction, and increasing shortage of affordable housing.

Utah does not have a statewide regulatory program to inspect and approve off-site construction. The state-level gap in the building codes led a local building official in Salt Lake City to find the emergent off-site standards and present them to the city council for adoption. The standards are designed to complement local building and residential codes, which allowed the city to readily adopt them into code.

Prior to the adoption of Standards 1200 and 1205, Salt Lake City mandated city building officials to inspect all construction projects within the jurisdiction. However, building officials were not allowed to leave the jurisdiction to conduct the required inspections. By limiting inspections and approvals to city building officials within the city jurisdiction, this regulatory structure effectively prohibited off-site construction. Standard 1205 provides an effective mechanism for third-party inspections that allow authorized delegates to complete in-factory code compliance inspections for the city. While reducing the burden on local building inspectors, Salt Lake City also opened the door for manufacturers to complete off-site projects in a city that was once off-limits.

While building officials saw value in filling a gap created at the state level and an opportunity to enhance the current code with an approval mechanism for off-site, the city council members considered the standards an enabler of the efficient creation of additional high-quality, affordable housing for constituents. Like many densely populated areas in the United States, Salt Lake City faces an affordable housing crisis exacerbated by the increasing cost of homeownership and rent. The adoption of the standards provided delineated roles for manufacturers, inspection officials, and building permitting agencies, and responsibilities and requirements for in-factory and on-site inspections. In the nine months after adopting Standards 1200 and 1205, Salt Lake City was able to increase housing in a quick and flexible manner. While the Standards are primarily used to inspect and approve the construction of prefabricated additional dwelling units (ADUs), the city recorded a substantial increase in housing: in less than a year, 30 ADUs were completed, 17 are in the inspection processes, 11 plans are under review, and 34 permits are pending. Salt Lake City also actively engages with off-site manufacturers to plan an affordable housing development of 50 units for low-income individuals and families.

The combination of these three factors made Standards 1200 and 1205 a natural fit for adoption for Salt Lake City, but any locality facing similar challenges could benefit from the mechanisms and frameworks in the standards. Salt Lake City is an example of using Standards 1200 and 1205 as a tool to ease regulatory barriers for off-site construction, complement local building and safety codes, allow for factory and third-party inspections to reduce the burden on local AHJs, create opportunities for off-site manufacturers, and alleviate the affordable housing crisis. The city’s forward-thinking perspective and benefits realized in under a year provide a compelling case for other states and jurisdictions to replicate.

How ABC Collaborative can Advance Off-Site Construction through Code Adoption

The ABC Collaborative report Market Opportunities and Challenges for Decarbonizing US Buildings presented stakeholder analysis identifying widespread confusion and frustration with applicable standards, building codes, permitting, and approval processes across multiple stakeholder types when discussing industrialized construction (IC), which includes prefabricated construction methods. Due to the regionality of building codes and standards and an inconsistent interpretation of applicable rules, code officials are often unfamiliar with new technologies or processes being implemented, leading to onerous scrutiny, construction delays, and sometimes unjust rejections.

Supply stakeholders articulated that amending building codes and standards to consider ABC processes will increase efficiency and reduce timelines in the approval and permitting processes. The ABC Collaborative facilitates a Working Group on Codes, Permitting, Testing, and Accreditation to assist in the widespread adoption of advanced building technologies by improving code uniformity, education, interpretation, and enforcement. The working group brings together subject matter experts and industry stakeholders for regular discussions on easing the barriers to off-site construction through mechanisms related to codes and standards. The Working Group is open to interested parties with relevant expertise — individuals interested in joining this ongoing work can contact the ABC Collaborative via this website.

Conclusion

The high level of building code fragmentation in the United States is evident in the varying levels of code adoption and enforcement, local nuances, and regulatory bodies responsible for off-site compliance programs at the state and local levels. The result is a building code landscape that is unnecessarily challenging and restrictive for the next generation of ABC practices. The lack of code consistency among different states and other jurisdictions hinders growth in the off-site construction industry and impedes economies of scale for off-site construction and innovative technologies. It also effectively restricts the areas where ABC materials and technologies can be efficiently deployed, which further deters innovation in the industry. On the surface, building codes might appear to be an unlikely lever to solve the complex challenges in the construction industry. A deeper look reveals building codes are one of the most effective tools to reduce institutional and market barriers for ABC. Standards 1200 and 1205 are tools available for states and localities to embrace off-site construction and deploy it to their advantage. In states and localities without off-site programs, the standards offer a clear and readymade pathway for the inspection and approval of off-site projects. In states with existing modular programs, the standards offer greater consistency across the code compliance landscape for builders. Effective mechanisms for off-site code compliance can promote widespread adoption of ABC.

B. PUBLIC Prefab and the domino effect of sustainable practices

EDIE DILLMAN Featured on Sketchup | sketchup.com

B. PUBLIC Prefab is a woman-owned public benefit corporation that brings sustainability to the building industry through prefabricated building panels. They use SketchUp to collaborate with their existing partners, draw new clients in, and win work.

Home completed using B. PUBLIC Prefab panels. All images courtesy of B. PUBLIC Prefab.

B. PUBLIC Prefab is a team of architects, designers, and change-makers united around sustainability. They believe building with prefabricated elements will help the architecture, engineering and construction (AEC) industry take a step toward a more sustainable future.

One of B. PUBLIC Prefab’s biggest challenges is figuring out how to communicate the myriad benefits of prefabrication to builders and decision-makers who could use the panels in their projects. Building envelopes have been built on-site for generations of builders, and big shifts in the construction process are never easy.

B. PUBLIC Prefab window panels on a construction site. All images courtesy of B. PUBLIC Prefab

In a conversation with B. PUBLIC Prefab’s Edie Dillman, co-founder and CEO, Natasha Ribiero, designer, and Brian Dieterle, architect, we learned more about how using prefabricated panels can boost efficiency in construction. They shared how prefabricated panels can change a builder's career for the better and how prefabrication can make their work sites leaner, cleaner, and greener. We also discussed how B. PUBLIC Prefab is leveraging SketchUp in its outreach efforts and in-house estimating and design.

Building sustainable workforces

A worker installing B. PUBLIC Prefab roof panels. All images courtesy of B. PUBLIC Prefab

It is mission-critical to B. PUBLIC Prefab that they support the careers that make their builds possible. People who work in construction are in a prime position to drive the industry toward global sustainability.

"There is such a crisis around the trades's workforce. Allowing people to work and have longevity in a trade career is really important to us."

Edie Dillman, co-founder and CEO, B. PUBLIC Prefab

B. PUBLIC Prefab holds quarterly in-person trainings to make using their panels more accessible for builders. At the trainings, builders learn how the panels work in a construction project, how to create an estimate for installation, and about the many advantages of prefab versus building on-site. B. PUBLIC Prefab invites builders to projects under construction so they can watch the panels in action as part of an actual build.

Through a consistent commitment to nourishing healthy, long-term careers in the building trades, B. PUBLIC Prefab hopes to inspire sustainable mindsets in the people who make up part of an industry that currently accounts for 39% of carbon emissions. Every person who understands the efficiencies of prefabrication can share that knowledge with colleagues and clients, tipping more dominoes toward a healthier planet.

On-site speed through off-site fabrication

Timelines for construction workflows: site built versus B. PUBLIC Prefab. All images courtesy of B. PUBLIC Prefab.

The trainings give builders a sneak peek into the cost and time-saving benefits of using prefabricated panels at the work site.

"Builders who've been building a certain way for many years come in and immediately recognize the benefits. Things they always have on their minds when building in the field are not issues with prefab.”

Brian Dieterle, architect, B. PUBLIC Prefab

In addition to speeding up build times and making budgets more predictable for contractors, prefab has a huge effect on a build site's ecological impact. Prefabrication is done to specification off-site, and the panels delivered are only those needed for the project. There is very little construction waste on prefab construction sites, eliminating the ubiquitous construction dumpster full of building materials destined for the landfill.

"If you look at a normal site-built home, the construction waste is pretty astonishing. To go to one of our installs and see how clean and seamless it is, it’s impressive and something that maybe people don't think about right off the bat when they think of prefab."

Natasha Ribiero, designer, B. PUBLIC Prefab

Interior of home in progress with B. PUBLIC Prefab wall panels. All images courtesy of B. PUBLIC Prefab.

There's little to no construction waste when the panels are fabricated. During a webinar with the staff at the fabrication shop in New Mexico, builders asked what the percentage of waste was. The team answered by panning the camera to four pieces of wood in the corner that were waiting to be reused.

"There's virtually no waste when we create the panels because it's controllable. On-site, it's hard to have the time or the energy to save cut ends, stack them, and bring them back somewhere else so that somebody else could use them. With prefabrication, it's a good reason to be under one roof and have all the material there so that when you need it, an extra piece is coming from scrap, and you're not cutting virgin lumber."

Edie Dillman, co-founder and CEO, B. PUBLIC Prefab

Prefab for happier, healthier homes

The more that people value sustainability, the more the demand for environmentally sound building practices will increase. B. PUBLIC Prefab's panels support this market growth by making it easy for builders and clients to continue making green choices.

Cost-reduction, comfort, and health

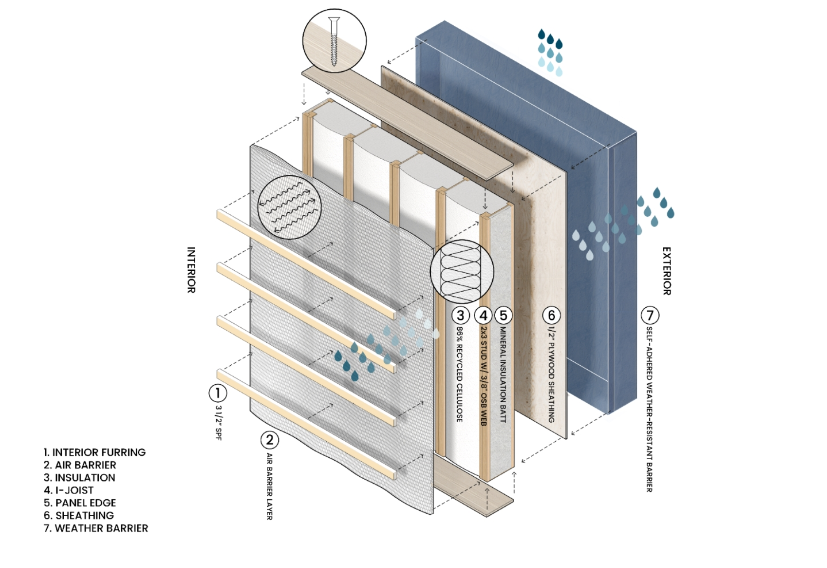

B. PUBLIC Prefab panel composition. All images courtesy of B. PUBLIC Prefab.

Dillman thinks that low, predictable energy bills are a matter of fairness. In today's changing climate, that's only possible with precise design and construction. In addition to the financial peace of mind, people who live in houses built with B. PUBLIC Prefab panels say they are ultra-comfortable. The well-insulated, non-toxic panels prevent air leakage for cleaner air and more soundproof homes.

"A sound artist moved into a house built with our panels in an area of northern New Mexico that has high winds 360 days a year. She was there for about three days when she called and said, 'Forget it. Stop selling houses. It's actually a sound studio. I've never experienced this kind of quiet.'"

Edie Dillman, co-founder and CEO, B. PUBLIC Prefab

As the climate crisis continues to wreak havoc on our outdoor spaces, builders and inhabitants alike will benefit from sustainable techniques for ensuring clean, healthy indoor environments.

The domino effect of sustainable choices

Attributes of B. PUBLIC homes. All images courtesy of B. PUBLIC Prefab.

When a person decides on sustainable, prefabricated envelopes for their home, Dillman contends that more sustainable decisions follow.

While B. PUBLIC Prefab is not an electric-only company, many homes using their panels are being built to that standard. If a homeowner considers putting gas into their future home, they have to account for a more robust ventilation system, which requires more energy than a system for an electric-only home. People tend to opt for something other than gas, avoiding unsustainable options that would mitigate the energy benefits of building an efficient home with prefab panels.

“Once you're on this path of sustainability, there are so many benefits to continuing. It doesn't make sense to diverge from that path because it is probably more costly, and you might have health effects from it."

Edie Dillman, co-founder and CEO, B. PUBLIC Prefab

Using SketchUp to tip the first domino

In construction, just as in many other industries, getting people to change how they've operated for decades can be an uphill battle. B. PUBLIC Prefab puts a lot of effort into educating architects and builders on the benefits of their panels and how they can fit into — and in many cases improve — their current construction process. B. PUBLIC Prefab uses SketchUp as a communication tool to reach AEC professionals who could benefit from prefabrication.

SketchUp for sequencing high-performance construction

B. PUBLIC Prefab construction sequencing using SketchUp. All images courtesy of B. PUBLIC Prefab.

B. PUBLIC Prefab construction sequencing using SketchUp. All images courtesy of B. PUBLIC Prefab.

One of the biggest challenges in construction is project management. The budget, scheduling, and organization of even the most minor construction projects can get complicated quickly. An additional challenge for B. PUBLIC Prefab is that most project management software isn't built to consider prefabrication. This makes it extremely difficult for B. PUBLIC Prefab to communicate budget and time-saving benefits to potential partners.

Examples of estimate models B. PUBLIC Prefab builds in SketchUp. All images courtesy of B. PUBLIC Prefab.

Examples of estimate models B. PUBLIC Prefab builds in SketchUp. All images courtesy of B. PUBLIC Prefab. (Click to scroll through images.)

SketchUp fills the information gap by showing builders how prefabrication can slide into their schedule and budget.

"We give them a tremendous amount of data upfront. We're doing SketchUp estimates within a week and giving them a concrete cost for our assembly. We’re giving them materials they can insert into their bids and their sequencing. SketchUp is how we communicate that information back to them."

Edie Dillman, co-founder and CEO, B. PUBLIC Prefab

Modeling sustainability in SketchUp

SketchUp models and layouts of B. Public Prefab homes. All images courtesy of B. PUBLIC Prefab. (Click to scroll through images.)

"SketchUp has made it really seamless and easy to build out the house in basically no time. I don't see another tool that could be as useful just to build it out quickly and to be able to see the panels and how they're laid out. It's an invaluable tool from our perspective.”

Natasha Ribiero, designer, B. PUBLIC Prefab

Communicating with SketchUp components

Prefab Home Assembly SketchUp Video - B.PUBLIC Prefab

B. PUBLIC Prefab uses SketchUp to communicate what’s possible with prefab to builders and architects. They invite fellow building professionals to experiment with prefabricated envelopes through a free downloadable .skp file that houses all their panel options, including walls, floors, roofs, panels with cutouts for windows, and more.

"It's fun for some people to go on our website and download the components and play around,” Ribiero told us. B. PUBLIC Prefab encourages people to use the components like Legos and experiment with panel combinations that could lead to unique designs and models.

B. PUBLIC Prefab hopes that more builders will open their minds to prefabrication and its benefits with increased access to their panels. AEC professionals who want to reduce waste and lower the carbon footprint of their projects can turn to prefab to build more sustainable homes more efficiently.

Sustainability is a part of SketchUp’s mission, too. Start a free SketchUp trial to experience how leveraging tools like PreDesign can give you insights into factors that will help you make sustainable choices — before you start modeling.

Click here to give B. PUBLIC Prefab panels a try in SketchUp.

Bonny Doon couple takes active role designing ‘passive’ home

Press Banner By: DREW PENNER June 2, 2023

From their perch in their home atop the mountain in Bonny Doon, partners Tonje Wold-Switzer and Sebastian Little took in a panorama of lightning strikes that would go on to devour more than 900 homes in the region, including theirs.

They were aware a storm was on its way, but to actually witness nature’s fury in full effect was arresting—particularly the rolling set of clouds that looked like an incoming tidal wave.

“It was like a tornado but super miniature,” Little said. “But it came and went. Like, really strange.”

The couple was lucky. First of all, their family survived. And because they’d just moved into the neighborhood, they had less of an emotional attachment to the property.

Along their reconstruction path, they’ve been hit by fewer regulatory hurdles than others in Santa Cruz County. They decided to lock in a contractor early, and were able to get started on construction quickly.

Thanks to some lucky breaks and decisive action, the family became one of the few CZU Lightning Complex Fire victims who have been able to move back to the North County.

In the process, they chose to embrace a new architectural trend they say helps tackle the root cause of the situation they found themselves in.

They decided, instead of rebuilding the classic ranch home with an atrium in the center they’d purchased, they’d move forward with a project that seeks to adapt to a world beset by climate change and increased forest fire risk.

Their solution? Erecting a so-called “passive home.”

This style of construction relies on new technology and building techniques to boost energy savings. It also taps into the natural features of the site to maximize sustainability, such as orienting structures to harness solar power.

Tonje Wold-Switzer shows plans for the “passive home,” which relies on new technology and building techniques to boost energy savings. (Drew Penner/Press Banner)

And on June 3, the public will have a chance to examine the design features the couple has become so passionate about during an open house from 10am-2pm at 131 Cottini Way in Bonny Doon, where curious souls can get tours of 13 electrification stations and speak to experts about the unique features.

This is not a marketing gimmick, they say—not by a long shot. They’re true believers.

“In general, people who have passive houses become evangelists for passive houses,” Little said. “We feel that way, too.”

Can you blame them? After all, they went through quite the ordeal.

It wasn’t that Wold-Switzer was unprepared for wildfire. In fact, she’d had to evacuate during an earlier blaze, back when she lived in Last Chance.

It was that experience—along with Community Emergency Response Team training—that taught Wold-Switzer what to do as the natural disaster unfolded.

“It was so ominous,” she said, noting at least they had N95 masks on hand, due to the ongoing pandemic. “You could only see a few feet in front of you.”

All told, the fire would take out nearly 1,500 structures throughout the Santa Cruz Mountains.

The couple and their two children had escaped danger by staying with friends for a few days. Then, they moved to a hotel in Santa Clara. Eventually, they found an AirBnB in Santa Cruz County, where they’d remain for almost two years.

Rebuilding after fire

As the couple began to pick up the pieces, they considered a number of different options.

“Through our investigation of building types that would go up fast and at a lower cost, we stumbled upon high-performance prefabs and then cellulose insulated passive homes,” Wold-Switzer said. “From there, going all-electric was a natural choice and furthered the alignment between our climate crisis concerns and our being part of the solution in the capacity of how we live and consume day-to-day.”

While passive residences often require electricity for lighting, electronics and heating water, by selecting energy-efficient appliances and relying on alternative energy (such as solar panels or wind turbines), owners can vastly reduce their reliance on the grid. Some studies point to a 90% increase in energy efficiency.

Wold-Switzer and Little decided on an assembled home that uses structurally integrated panels (SIP).

“We found sort of a hybrid model,” Little said.

Sebastian Little and Tonje Wold-Switzer hope others will embrace their energy-efficient approach to wildfire recovery. (Drew Penner/Press Banner)

Green advocates are hoping to see an uptick in residential design efficiency, particularly in the wake of the passage of the Inflation Reduction Act, which has unleashed up to $14,000 for households interested in switching from gas to electric appliances.

Wold-Switzer and Little teamed up with B.Public Prefab out of Santa Fe, N.M., for the architectural drawings, as they worked with 4Leaf Inc., the County’s contractor, to win approval for their dream home.

Benjamin Riordan, another Bonny Dooner, was the contractor they selected to put the puzzle pieces into place. Three months after signing with B.Public, in March 2021, site work began. They had a foundation poured by August, and last June marked their triumphant return.

Little says they went with a muted blue tone for the exterior to soften the sharp modern aesthetic, which includes corrugated metal and concrete.

Now they’re hoping to convince others to embrace their energy-efficient approach to wildfire recovery.

“What I learned about passive homes during the process that I wasn’t aware of—that added tremendously to my resolve about building one—was the fire resiliency,” Wold-Switzer said. “And I think there’s an opportunity for policy advocacy on the state and local level to incentivize climate-adaptive building models.”

The community is invited to their open house on Saturday, June 3, from 10am-2pm at 131 Cottini Way in Bonny Doon.

Changing the Way We Build - B.PUBLIC Prefab

EDIE DILLMAN Featured on Go Solo | subkit.com

Interested in starting your own entrepreneurial journey in home care but unsure what to expect? Then read up on our interview with Edie Dillman, Co-Founder of B.PUBLIC Prefab, located in Santa Fe, NM, USA.

What's your business, and who are your customers?

B.PUBLIC Prefab is a team of architects, designers, and change-makers meeting the climate and housing crises head-on. We're reimagining building for the better with technology that achieves extreme energy reduction, deep sustainability, and unmatched livability. We work with clients directly to design customer homes, architects and designers designing with our prefab components for high-performance buildings, and developers building NetZero and sustainable communities.

Tell us about yourself

I came to B.PUBLIC Prefab from the Education-to-Workforce disruption. At the same time, my partner was creating the first line of standard building components that would be rolled out as B.PUBLIC Prefab; I was working with a nonprofit addressing critical skills gaps in our workforce and innovative ways to train and attract talent to high-demand career paths. The eureka moment that inspired me to start B.PUBLIC Prefab was that labor shortages in the trades were the result of 30 years of attrition. We cannot solve that gap in skills and experience without out-of-the-box (or in-the-shop) disruption. We need to think smarter, work more efficiently, and attract huge numbers of new and diverse workers to fill not just the workforce crisis - but the housing shortage and rising construction costs. I realized that by creating jobs that train tradespeople and, importantly, offer job security and transferable skills with meaningful pathways, we might be able to create a shift. And the kicker for me is that our technology is also the future of sustainable housing and energy-independent healthy homes. B.PUBLIC Prefab allows me to make an impact on multiple issues while focusing on growing our one company.

What's your biggest accomplishment as a business owner?

I am very proud of building something that is segment-defining out of nothing. Of course, I am also incredibly proud and grateful that we could survive launching a company at the exact time COVID threw the business world upside down. Being an entrepreneur always has unexpected twists - and COVID certainly taught us that by being a mission-based public benefit corporation, it is helpful to have a central focus on solutions when the world goes sideways - our focus was clear.

What's one of the hardest things that comes with being a business owner?

Sleep can be a challenge. Both the thrilling and the worrying thoughts can keep you up or wake you up. I love my work and have a hard time turning it off. Lots of people preach about taking good care of yourself as crucial for the health of the company and your ability to be at your top performance. I have a hard time with that balance and will always have to practice walking away from the computer or prioritizing a hike to stay balanced.

What are the top tips you'd give to anyone looking to start, run and grow a business today?

Don't quit your day job until you have an MVP.

Surround yourself with great advisors and ignore the folks to eat your time and don't feed your progress.

Make sure you focus on doing better for the planet, people, or a purpose. Profit is no longer enough, and money will not keep you working through the hard parts. It helps to know you have a larger purpose and that your work is service.

Where can people find you and your business?

Website: https://bpublicprefab.com/

Facebook: https://www.facebook.com/BPUBLICprefab

Instagram: https://www.instagram.com/b.publicprefab/

LinkedIn: https://www.linkedin.com/in/edie-dillman-159a639/

If you like what you've read here and have your own story as a solo or small business entrepreneur that you'd like to share, then please answer these interview questions. We'd love to feature your journey on these pages.

Turn your craft into recurring revenue with Subkit. Start your subscription offering in minutes and supercharge it with growth levers. Get early access here.

B.PUBLIC Receives JTIP Funding for 12 New Green Jobs

B PUBLIC Prefab, PBC , Santa Fe and Las Vegas, N.M. 16 trainees. Santa Fe location

seeks to hire 4 trainees at an average wage of $28.88 for a total award of $62,494.08 and

Las Vegas has been approved for 12 trainees at an average wage of $25.76 for a total award

of $195,165.28. B.PUBLIC Prefab is a woman-owned Public Benefit Corporation (PBC)

with explicit goals to create regional green jobs and make corporate decisions that protect

the environment and increase accessibility to high-performance buildings for all new

construction. B.PUBLIC Prefab wall system creates high-performance building envelopes

for new residential construction. This is their first JTIP application.

Photo: B.PUBLIC Training

OffsiteDirt.com Highlights Pilot Builder Training Event

The flyer waves like a flag. Las Vegas, New Mexico has a new wall in town thanks to our PHriends at B.Public Prefab. Their commitment to the development of regionally focused green manufacturing and builder training is taking a great stride this season. The launch of a new R&D manufacturing facility in Las Vegas, NM and the hosting of our first builder training event in December is a great way to wrap up an active 2022 and boost the 2023 construction season.

"Several of us from High Country Timber frame attended the B.Public Prefab installer training in Las Vegas, New Mexico and we came away very impressed with the B.Public panelized system, its overall simplicity for efficient installation, and its proven high performance application for net-zero and passive house standard projects. Working with a well thought out and engineered high performance panelized system, with modern quality control processes integrated into the manufacturing line, allows me to proceed with confidence when recommending the B.Public system to our clients. Our goal is to introduce net-zero and passive house methods, materials, and standards to all of the homes we design/ build moving forward and I anticipate that B.Public will be a perfect partner in that endeavour. I've had two promising discussions with clients already just since returning from the training about using the B.Public system for their upcoming projects. Moving forward on the right path is a necessity for conscientious designers and builders as we have a critical moral and ethical role to play in the energy consumption arena in the days, months, and years to come."

--Tom Ortiz-Owens, High Country Timberframe and Gallery Woodworking, Boone, N

Johnny Rezvani of 475 said, "Being able to train multiple crews from different locations across the country all at once is representative of the way prefab panelization is able to scale. This method of construction is the most exciting growth area we're seeing in North America and is changing the game for the high-performance industry."

OffsiteDirt: Women in Building

“If it was easy, everyone would do it. Get up and keep running."

Edie Dillman is CEO and co-founder of B.Public Prefab – a component-based high-performance building company that prioritizes energy reduction and housing creation. As co-founder of a decidedly disruptive company, she is committed to systems change and the rapid adoption of solutions for the natural and the built environment.

What attracted you to your role/position?

I hit a moment in my career (or a specific birthday) where it was impossible for me to ignore the environmental crisis. I was in the very fortunate position of having an opportunity to start a new company with an off-site approach developed by my business partner. Honestly, it was a crazy leap of faith without a safety net. But playing it safe is not where change comes from and if we can do good in this lifetime I feel we must. So, this was my chance to help protect our planet, build homes, create some green jobs and share the great news that there is so much we can do. Go big or stop complaining - so I chose action and I am so thrilled to share our journey.

What are your goals for the next 24 months?

Triple our company! I want to grow our staff, manufacturing capacity, and the number of low-energy healthy housing units built with B.PUBLIC. We are in a growth surge and I feel like we are running at full speed for the next couple of years. We launched the company two years ago and thinking forward to the next two is so exciting. Yes, some days the to-do list and ambition for B.PUBIC is daunting - but it is also a privilege and a joy to help improve the building industry. Off-site construction and the next generation of green building is here and the next 24 months is going to be huge.

How will this company impact others?

This is a big one! Let me climb up on my soapbox for a moment. The number one impact is to improve the health of occupants of our homes. The indoor air quality and thermal comfort is our number one outcome - and it is a huge benefit to all that this is achieved by consuming radically less energy and carbon.

Today we are helping ten families rebuild from wildfires. Getting people home and safe is the kind of impact we want to have. Our homes are built for generations of permanent low-energy and resilience.

What are the latest trends in high performance?

Craftsmanship is trending! Pride in detail and good materials! Something so old-fashioned is trending. We are seeing this sweet twist on pride and high-tech materials.

Do you have a quote or montra that keeps you inspired? If not, how do you keep moving forward?

“If it was easy - everyone would do it.” Get up and keep running.

Drop the Hammer | Santa Fe Report May 18, 2022

B.PUBLIC Prefab is designing homes for a changing climate

by Julia Goldberg

Between 2014 and 2020, the running five-year average annual number of structures destroyed by wildfires rose from 2,873 to 12,255—a fourfold increase in just six years.

This sobering statistic appears in a January report from the federal government, produced by the US Agriculture Department and Forest Service. “Confronting the Wildfire Crisis: A Strategy for Protecting Communities and Improving Resilience in America’s Forests” details some of the devastating impacts from recent wildfires to both human life and structures. Those stats include the fall-out from the 2021 Dixie Fire in California, which burned nearly one million acres, killed one person and destroyed 1,329 structures. Colorado’s Marshall Fire wasn’t included in the report, but Boulder County estimates in January said that fire had consumed more than 1,000 structures.

The threat to homes is only likely to increase, according to a report released this week by the nonprofit First Street Foundation, which forecasts close to 80 million structures—residential and commercial—could experience some level of destruction from wildfire in the next 30 years. New Mexico ranks among the top states (California is the top) with the highest proportion of properties at such risk.

B.PUBLIC Prefab co-founder and CEO Edie Dillman wasn’t necessarily envisioning a roster of clients whose homes had been lost to wildfire when she launched her company in January, 2020 after a year of business planning with partners Jonah Stanford—to whom Dillman is married—and Charlotte Lagarde, who serve as the company’s CTO and COO, respectively.

Dillman was, however, thinking about climate change.

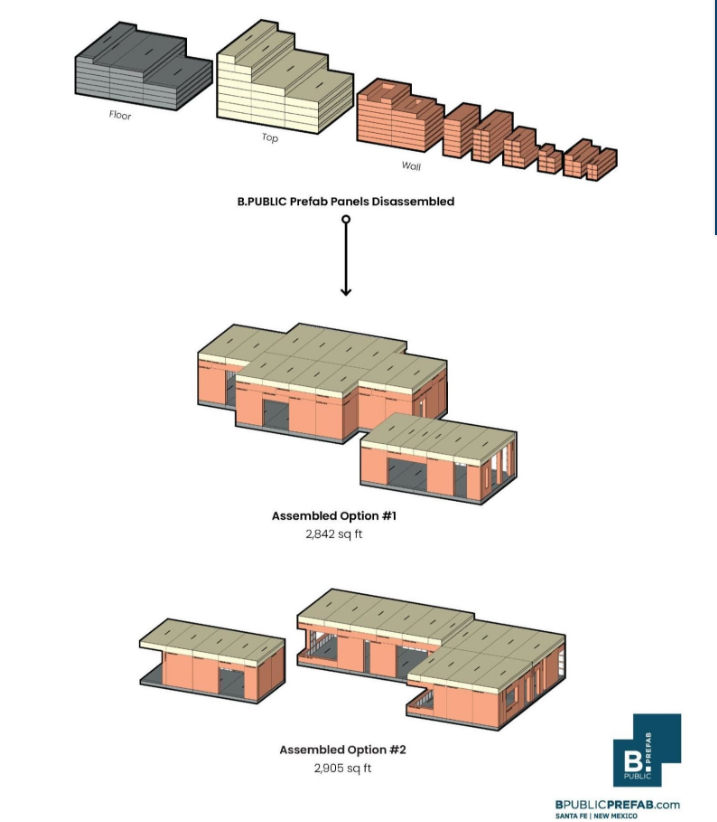

B.PUBLIC provides panelized construction systems: standardized and prefabricated walls, floors and roofs, designed for low-energy use and high performance. The company describes the product as being “LEGO-like”—a tool architects and designers can use and customize—with 80% energy savings, 90% less construction waste, 30% faster construction and 90% carbon positive materials.

Dillman says the company initially identified New Mexico, as well as Northern California, Colorado, Utah and Arizona, as " big growth markets with really challenging…climate conditions to achieve a low energy, very comfortable house.”

New Mexico Inno | BizJournals.com May 17, 2022

Santa Fe company has eyes on a manufacturing facility for passive house components

By Collin Krabbe

Ever see a stack of newspapers and wonder: “why haven’t these gone in the trash?”

Well, a Santa Fe startup has a different idea — and it’s not about saving money on gift wrap during the holiday season. Instead, the firm provides the backbone for homes insulated with newspaper.

The company, called B.PUBLIC Prefab, subscribes to a growing building standard called “passive house,”focused on energy savings. Now the startup, which was founded in 2019, wants to open a manufacturing facility in New Mexico along with contract producers in other places.

In an interview on May 17, cofounder and CEO Edie Dillman spelled out the origin story and concept behind B.PUBLIC Prefab and its prefabricated building blocks.

"We do the off-site framing, sheathing, insulation, weather barrier and air barrier of the primary building envelope," Dillman said.

Those parts can then be finished off with other interior and external materials. The company has a focus on markets with high housing demand, a shortage of builders and where code, policy and incentives are geared toward what the company provides.

Dillman said that in 2019, the startup purchased intellectual property from NEEDBASED, a design practice with a focus on sustainability from Jonah Stanford, one of three co-founders at B.PUBLIC. Charlotte Lagarde, a filmmaker who Dillman said was looking to pivot her career to environmental justice, is the third cofounder.

"Effectively, passive house approach allows for a conservation of energy for heating and cooling of 80 to 90 percent above a standard code home," Dillman said. "So we're talking net-zero, nearly net-zero."

B.PUBLIC is located at the Santa Fe Business Incubator with plans to open the New Mexico facility in the next one to two years. For buildings outside the Southwest, B.PUBLIC will use contract manufacturers. Similarly, for all projects, the company will enlist others to assemble the final product.

The six-employee company has already raised $750,000 in debt funding, according to Dillman.

B.PUBLIC on the road | Boulder and Denver November 2021

Jonah & Edie hit the road to meet with Passive House and green building professionals in central Colorado.

They met up with our great friends in Passive at Emu Systems at the Colorado Passive House Happy Hour & Mini-Expo. What a blast to connect with other innovators and builders making a difference in the built environment, with BEER!

The Colorado Green Building Guild hosted us for a live presentation and conversation at the Environmental Design Department on the CU Boulder campus. Thank you to all the curious and talented builders, architects, and students who joined us and to the CCBG for inviting us! We had a great time and apologize for the dark video - but happy to do it all over again soon! Great partnerships and ecosystem being supported by CGBG!

We look forward to continued partnerships with organizations like these that are supporting and inspiring building professionals to go green!

AIA Santa Fe Award | 2021 Design ExcellencE Merit Award

Our first project in Santa Cruz California was recognized by the Santa Fe AIA chapter at their annual gala and awards ceremony. We were selected from a group of distinguished projects. The ROBIN HOUSE presentation boards from the in-person event are below. Congratulations to Lead Architect JD Scott, Project Manager Charlotte Lagarde, Builder Benjamin Riordan, our install team and manufacturing partners at Collective Carperrnty, and our wonderful clients on this home! Award-winning high-performance home design, permit, to install the structural thermal envelope in six months! We are so proud and honored for this recognition.

Climate Change Leadership Institute Innovation Award

WOW!

What a way to end 2021 by receiving this award! See letter and kind words of encouragement and acknowledgement from CCLI.

House Building — Praise for Passive House design

Santa Fe New Mexican HOME Sunday, November 6, 2021

What makes a house feel like home? When it is quiet and peaceful? Full of natural light during the day and good-and-dark at night for sound sleep? With favorite art on the walls and books unpacked on their shelves? Some might say when it smells like fresh baked cookies (or enchiladas). For New Mexicans, we can feel home in a double adobe; an unmistakable solid, quiet, grounded feeling of a craft-made home.

As one of the co-founders of B.PUBLIC Prefab based in Santa Fe, I spend my work life talking to people about building differently with deeply insulated walls to achieve Passive House-like performance for new home construction. Because Passive House is still relatively young in the U.S. (12 years as compared to Germany's 30), very few new home customers have ever experienced being in, let alone living in, a house built on such rigorous energy-efficiency principles.

The Passive House system is, admittedly, a rather technical and complicated design to understand. The main thing many people I talk to are interested in knowing is: How does it feel? Is a home that uses 80% less energy uncomfortable or seem like a sacrifice? I find myself using my hands, gesturing over Zoom and relying on metaphors to answer. For example, I will ask people if they remember the first time they experienced radiant floors in winter and how relaxing it was on their bodies. What a thing to have warm feet and relaxed shoulders! Passive homes are kind of like that, but with the additional gift of being so well-insulated and comfortable, from head to feet, that you always feel warmed like that, except without the heat on.

It is lovely to meet with clients in New Mexico because I can use the experience of adobe as a comparison to a Passive House in that Passives are incredibly quiet, have deep-set windows and provide an utterly relaxing sense of home within 17-inch-thick walls. New Mexicans also understand right away that things made with craft, care and natural materials feel like home and also last like a home should—for generations.

Outside of New Mexico, it gets a little tricky. For those folks in California, for example, I sometimes compare Passive House to having things in common with a Tesla: they’re both electric and super quiet. Passive homes are designed to be electric-only, for indoor health and energy conservation. They are 50% quieter, compared to code construction, due to well-insulated envelopes, paired with high-performance windows.

Clearing up some confusion For folks across the Southwest who confuse Passive House with Passive Solar, I use one of my favorite working metaphors: the stainless steel thermos. Passive homes are made to be inactive like an insulated thermos. Passive, in the sense that the interior stays hot by holding in the heat effortlessly, by design, rather than needing energy added to it to keep warm.

I understand why there may be confusion. It is difficult to truly share all of the amenities and attributes of the Passive system of construction on the page or computer screen. You must step inside a Passive Home to sense the fullness of its warmth and serenity. It's a surround-sound of comfort.

More and more builders are proudly joining New Mexico’s long history of green building with some new ways to save the planet. In the process, they are still honoring what home should feel like for everyone.

Edie Dillman is CEO and co-founder of B.PUBLIC Prefab—a component-based high-performance building company that prioritizes energy reduction, carbon-positive materials, housing creation and community collaboration.

About Passive House

Passive House buildings are healthy, comfortable, efficient and cost less to operate. Passive House design can create any architectural style and any building type, providing a predictable pathway to net zero energy and zero carbon building. Science-based design principles and tools optimize both building performance and cost.

For more information: www.passivehouseaccelerator.com

B.PUBLIC on the road | Upstate NY and Ontario Canada

Edie and Charlotte hit the road to meet with building professionals and prefab manufacturers in update NY and Canada.

Our great friends in passive house at Simple Life Homes gave us a tour of their facility and a recent install. What a great team and mission!

Next, they headed to Farmington, New York to meet up with New Energy Works, timber framers building high-performance panels for sustainable buildings. Just our kind of folks!

We look forward to continued partnerships with craftsmen like this who are enthusiastically changing the world one high-performance prefab building at a time.

Exciting news! Affordable housing development in Santa Fe

In October, we partnered with Habitat for Humanity to submit qualifications for an RFQ to the City of Santa Fe for the development of green affordable housing. The City has selected our proposal!

We are honored to work with Habitat to provide our hometown community with building systems that prioritize sustainability, reduce carbon footprint, and resilience for equitable development!

The property is a small, but desirable piece of property just blocks from the historic plaza on the Santa Fe River.

The six-unit multi-family complex will use B.PUBLIC pre-fabricated wall and ceiling panels for the building thermal envelope of each unit.

The building will meet Energy Star energy efficiency requirements and Net-Zero Energy-Ready, exceeding the standards established by the City of Santa Fe’s Green Code.

The units will be all-electric, equipped with energy-efficient electric appliances, LED lighting, a rooftop solar array, a hybrid electric water heater to maximize efficiency, and an Energy Recovery Ventilation System (ERV) to ensure clean and healthy air for occupants.

Maximizing efficiency and installing solar will allow the building to produce more energy than it consumes on an annual basis.

This will be a competitive process and we are gratified by our developing relationship with Habitat for this or future projects.

This is exactly the kind of non-profit relationship core to our mission for equity in housing.

The Greenest home in Bonny Doon - CZU Rebuild September 2021

““We believe this can be the new normal for building and rebuilding in California.” ”

Our clients had just replaced all the windows in their newly purchased home in the Santa Cruz Mountains before the CZU fire destroyed it in 2020. When they looked to rebuild, they wanted more than efficient windows – they wanted a super-efficient home that requires less energy, offers greater comfort, is kind to the environment, and could offer them peace of mind. They wanted a home that would suit their desire to get close to Passive House performance while getting away from polyurethane foam insulation.

An ordinary site-built home may take three months to frame, wrap, and insulate. A performance home that requires air sealing, continuous insulation, and a weather barrier to protect the home’s integrity may take even longer. The B.PUBLIC Prefab off-site panelized structure allow the building envelope (shell) for new homes to be installed in a matter of days instead of months.

The first email through design, permitting, and final installation took six months. The install process took a total of 3 days.

California’s housing crisis is in dire need for solutions to build faster and greener. Its newly mandated focus on solar and renewables is only a portion of what we need to fix. “When you consider that 40 percent of all pollution is caused by the construction and running of buildings, it is urgent that we change the way we build,” says chief operating officer Charlotte Lagarde. “At B.PUBLIC we tackle both sources of carbon emission by prioritizing deep energy conservation in our designs and the materials we use. The good news is that there is a carbon smart way to build craftsman comfort, low-energy, and resilient homes. It’s just a mind shift ”

““From the tragedy of so many homes lost to fire - we believe that if you are going to rebuild there needs to be heart and the environment central to the project. We are honored to help one home at a time” ”

B.Public’s Passive House-quality prefabricated wall, roof, and floor panels are designed to speed construction, ensure quality craftsmanship, and reduce a building’s energy consumption by up to 90% over its lifetime, while utilizing recycled and petroleum-free materials.

““While building a home was never part of our plan or dream and we entered the process reluctantly, working with B.Public has become another step in our journey to living more sustainably through building a resilient and efficient home. We are excited to share our experience with our fellow fire families, and we hope BPublic’s expertise can support many others in coming home soon,””

Word is spreading through the neighborhood network about this sustainable alternative - building beyond code and with great architectural style. We are working with families in Boulder Creek and Bonny Doon who are designing and rebuilding with B.PUBLIC Prefab with the goal to move back home quickly.

B.PUBLIC Microhome Competition 2021 - Shortlisted!

ABOUT THE COMPETITION:

The MICROHOME 2021 Competition challenged architects from all over the globe to submit designs for an off-grid, modular structure for a hypothetical young professional couple. The competition encouraged out-of-the-box thinking, pushing architects to rethink spatial organization and include new technologies, unique aesthetics, and innovative materials. The only requirement was not to exceed 25m², 269 sqft.

B.PUBLIC SUBMISSION: Casa Calibri

Santa Fe, New Mexico faces an affordable housing crisis. The city’s rental market is among the least equitable in the US, with a deficit of 7,300 units. This shortage has triggered a 46% increase in rent since 2016. Rent for a one-bedroom apartment now approaches $1,400. The COVID-19 pandemic has precipitated an influx of retirees and wealthy remote workers, causing home prices to skyrocket. In 2021, the mean home price reached $600; a couple would need to earn 120,000 per year to afford this price, twice the city’s median household income.

As a result of these historic shifts, Santa Fe has seen an exodus of educators and young creatives. If current trends continue, the very people who drive the vibrant cultural economy of Santa Fe will be priced out. The city government is seeking proposals for public-private developments on city-owned land.

Casa Calibri envisions a dense, off-grid community of micro homes clustered around shared open space on a parcel currently held by the city. As a grassroots housing cooperative the development targets teachers and young workers employed in Santa Fe’s arts & culture sector. Utilizing an innovative and cost-competitive system of prefabricated panels and Passive House performance, the project will set a new standard for resilience and low-carbon construction while fostering the next generation of Santa Fe’s workforce.

The project is 249 sqft and build with B.PUBLIC high-performance prefab panels. Additionally, the design includes a solar array, a rainwater harvesting system, and an ERV system that maximizes the home’s efficiency.

B.PUBLIC Team: Natasha Ribeiro & JD Scott, AIA

Congratulations on the great work on this project. Check out the International Projects Winners. linked

Climate Action Passive House Accelerator Magazine Winter 2022: BOOSTING Passive House AVAILABILITY

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

A Note from the Passive House Accelerator

As we ring in 2022, the Passive House Accelerator magazine once again brings encouraging stories of project teams, policymakers, and manufacturers delivering climate-friendly building solutions. Passive House techniques—in concert with building electrification, clean energy, and low embodied carbon materials—chart a clear pathway toward climate action for the building sector. We hope the practical guidance found in these pages will inspire imitations galore. And, while we are always excited to document the increasing adoption of Passive House approaches, in this issue, we are particularly thrilled to have an article by José Sosa Rueda covering the growth of Passive House in Latin America. Download the magazine here.

Boosting Passive House Availability